Menene ya kamata ya zama rata tsakanin fistan da silinda

Abubuwa

Don tabbatar da babban matsawa a cikin injin, kuma wannan yana rinjayar tasirinsa sosai da sauran damar iya aiki dangane da fitarwa, sauƙi na farawa da takamaiman amfani, pistons dole ne su kasance a cikin silinda tare da mafi ƙarancin izini. Amma ba zai yiwu a rage shi zuwa sifili ba, saboda yanayin zafi daban-daban na sassan, injin zai matse.

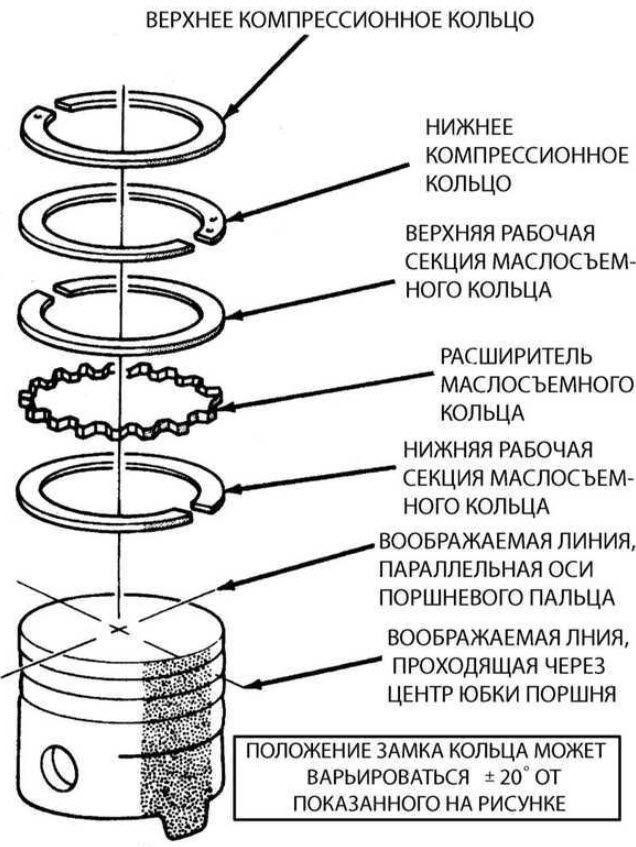

Sabili da haka, an ƙayyade ƙaddamarwa ta hanyar ƙididdigewa kuma an kiyaye shi sosai, kuma ana samun hatimin da ake bukata ta hanyar amfani da zoben piston na bazara a matsayin hatimin gas da man fetur.

Me yasa keɓancewa tsakanin fistan da silinda ke canzawa?

Masu zanen mota suna ƙoƙari su sanya sassan injin suyi aiki cikin yanayin gogayya ruwa.

Wannan hanya ce ta lubricating wuraren shafa yayin da, saboda ƙarfin fim ɗin mai ko kuma samar da mai a ƙarƙashin matsin lamba kuma a cikin adadin da ake buƙata, haɗin kai tsaye na sassan ba ya faruwa ko da a ƙarƙashin nauyi mai mahimmanci.

Ba koyaushe ba kuma ba a kowane yanayi ana iya kiyaye irin wannan jihar ba. Dalilai da yawa suna yin tasiri akan wannan:

- yunwar mai, samar da ruwa mai lubricating, kamar yadda aka yi a cikin bearings na crankshaft da camshafts, ba a yin shi a ƙarƙashin matsin lamba a cikin yanki tsakanin fistan da silinda, da sauran hanyoyin lubrication ba koyaushe suna ba da sakamako mai ƙarfi ba, mai na musamman. nozzles suna aiki mafi kyau, amma saboda dalilai daban-daban sanya su cikin jinkiri;

- Tsarin honing mara kyau ko sawa a saman silinda, an tsara shi don riƙe fim ɗin mai kuma ya hana shi bacewa gaba ɗaya ƙarƙashin ƙarfin zoben piston;

- cin zarafi na tsarin zafin jiki yana haifar da zeroing na thermal rata, da bacewar Layer mai da kuma bayyanar da zira kwallaye a kan pistons da cylinders;

- da yin amfani da low quality-man fetur tare da sabawa a duk muhimman halaye.

Da alama abin ban mamaki ne, amma saman silinda ya fi gajiyawa, kodayake galibi ana yin shi da ƙarfe na simintin gyare-gyare, ƙaƙƙarfan shingen simintin ƙarfe ne ko busassun jika iri-iri da aka jefa a cikin aluminium na toshe.

Ko da hannun riga ya ɓace, saman silinda na aluminum yana ƙarƙashin kulawa na musamman, kuma an ƙirƙiri wani sutura na musamman mai jure lalacewa.

Wannan shi ne saboda matsa lamba mafi tsayi a kan piston, wanda, a gaban lubrication, kusan ba ya cire karfe daga gare ta yayin motsi. Amma Silinda ne batun m aiki na spring zobba tare da high takamaiman matsa lamba saboda kananan lamba yankin.

A dabi'a, fistan kuma ya ƙare, ko da ya faru a hankali. Sakamakon jimlar lalacewa na bangarorin biyu na jujjuyawar, tazarar tana ci gaba da ƙaruwa, kuma ba ta dace ba.

Biyayya

A cikin yanayin farko, Silinda ya cika daidai da sunansa, adadi ne na geometric tare da diamita na dindindin akan tsayin duka da da'irar a kowane sashe daidai da axis. Duk da haka, piston yana da siffar da ya fi rikitarwa, baya ga haka, yana da abubuwan da ake sakawa na zafi, wanda sakamakon haka yana fadada rashin daidaituwa yayin aiki.

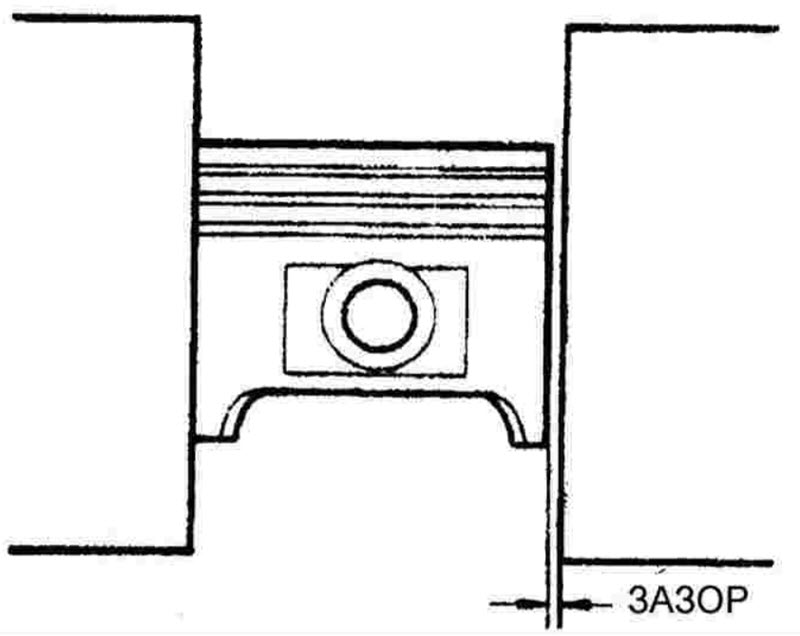

Don tantance yanayin rata, an zaɓi bambanci a cikin diamita na piston a cikin yanki na siket da silinda a tsakiyar ɓangaren sa.

A bisa ka'ida, ana la'akari da cewa ratar thermal ya kamata ya zama kusan 3 zuwa 5 daruruwan millimeters a diamita don sababbin sassa, kuma matsakaicin darajarsa a sakamakon lalacewa kada ya wuce 15 daruruwan, wato, 0,15 mm.

Tabbas, waɗannan su ne wasu ƙima masu mahimmanci, akwai injunan da yawa da yawa kuma sun bambanta duka a cikin hanyoyin ƙira daban-daban kuma a cikin ma'auni na geometric na sassan, dangane da ƙarar aiki.

Sakamakon cin zarafi

Tare da karuwa a cikin rata, kuma yawanci ana danganta shi da lalacewa a cikin aikin zoben, ƙarin man fetur ya fara shiga cikin ɗakin konewa kuma yana kashewa akan sharar gida.

A ka'ida, wannan ya kamata ya rage matsawa, amma sau da yawa, akasin haka, yana ƙaruwa, saboda yawan man fetur a kan zoben matsawa, rufe gibba. Amma wannan ba na dogon lokaci ba, zoben coke, kwanta, kuma matsawa ya ɓace gaba ɗaya.

Pistons tare da ƙarin izini ba za su iya yin aiki akai-akai kuma su fara bugawa ba. Ƙwaƙwalwar fistan a fili yana jin motsin motsi, wato, a cikin matsayi na sama, lokacin da ƙananan kan sandar haɗi ya canza hanyar motsi, kuma piston ya wuce tsakiyar matattu.

Siket ɗin yana motsawa daga bango ɗaya na Silinda kuma, zaɓin rata, ya buga kishiyar da ƙarfi. Ba za ku iya hawa tare da irin wannan sautin ba, piston zai iya rushewa, wanda zai haifar da bala'i ga dukan injin.

Yadda ake bincika sharewa tsakanin fistan da silinda

Don bincika tazarar, ana amfani da kayan aunawa a cikin nau'in micrometer da ma'aunin ciki, wannan biyun yana da daidaitattun aji wanda ke ba ku damar amsa kowane ɗari na millimeter.

Micrometer yana auna diamita na piston a cikin yankin siket ɗin sa, daidai da yatsa. Ana gyara sandar micrometer tare da matsewa, bayan haka an saita ma'aunin ciki zuwa sifili yayin da yake ajiye titin aunarsa akan sandar micrometer.

Bayan irin wannan sifili, mai nuna alamar caliper zai nuna sabani daga diamita na piston a cikin ɗaruruwan millimeters.

Ana auna silinda a cikin jirage uku, na sama, tsakiya da ƙasa, tare da yankin bugun bugun piston. Ana maimaita ma'auni tare da axis na yatsa da kuma fadin.

A sakamakon haka, ana iya tantance yanayin silinda bayan lalacewa. Babban abin da ake buƙata shine kasancewar rashin daidaituwa kamar "ellipse" da "mazugi". Na farko shine karkacewar sashin daga da'irar zuwa oval, na biyu kuma shine canjin diamita tare da axis na tsaye.

Kasancewar karkatattun kadada da yawa yana nuna rashin yiwuwar aiki na yau da kullun na zobba da buƙatar gyara silinda ko maye gurbin toshe.

Masana'antu sukan sanya wa abokan ciniki taron toshe tare da crankshaft (gajeren toshe). Amma sau da yawa ya juya ya zama mai rahusa don gyarawa tare da guntu, a cikin lokuta masu tsanani - tare da hannun riga, tare da maye gurbin pistons tare da sabon ma'auni ko girman girman pistons.

Ko da ba sababbin injuna tare da daidaitattun pistons ba, yana yiwuwa a zaɓa daidaitattun abubuwan sharewa. Don yin wannan, ana rarraba pistons zuwa ƙungiyoyi tare da karkatar da diamita na ɗari. Wannan yana ba ku damar saita rata tare da cikakkiyar daidaito kuma tabbatar da ingantaccen aikin motar da rayuwarta ta gaba.