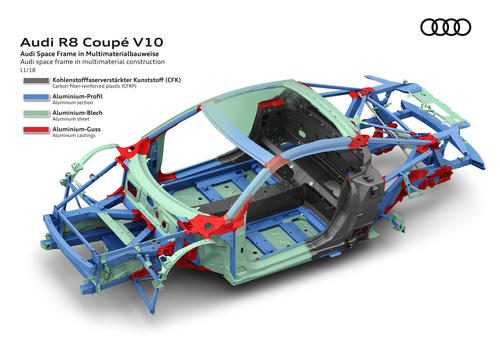

ASF - Audi Space Frame

ASF ya ƙunshi galibin rufaffiyar sassan sassan da aka fitar da ke haɗa juna ta hanyar gyare-gyaren majalisai. A cewar Audi, sake yin amfani da shi ya ninka na karfe sau biyar.

Jimlar makamashin da ake buƙata don samarwa shine 152-163 GJ idan aka kwatanta da 127 GJ don irin wannan keken ƙarfe.

Extruded

Ainihin, an yi su tare da bayanin martaba na akwatin. Alloys ɗin da aka yi amfani da su ba a buga su ba Al-Si gami da abun ciki na Si wanda ya fi 0,2% don tabbatar da iya gudana da taurin hazo yayin tsufa na wucin gadi.

zanen gado

An yi amfani da su don fale-falen da ke ɗaukar kaya, slabs, rufi da bangon wuta, suna da kashi 45% na nauyin tsarin. Kaurin su shine sau 1.7-1.8 ya fi girma fiye da na karfe. Alloy 5182 da aka yi amfani da shi a cikin jihar T4 (mafi nakasa) tare da iyakar 140-395 MPa. Ana iya dorewa duk da samun kasa da 7% magnesium saboda kasancewar sauran masu haɗin gwiwa.

Raka'a

Ana amfani da su a cikin yankunan da ke da matsala mafi girma.

Ana aiwatar da su ta hanyar amfani da tsari mai suna VACURAL, wanda ya haɗa da allurar ruwa na aluminum a cikin injin injin don samun:

Babban inganci da daidaituwa, ƙarancin ƙarancin ƙarfi don tabbatar da kaddarorin injiniyoyi masu haɓaka tare da taurin da ake buƙata don juriya ga gajiya;

Kyakkyawan weldability da ake buƙata don haɗawa da bayanan martaba.

Hanyoyin haɗi

Ana amfani da dabaru da yawa:

MIG waldi: ana amfani da shi don ƙananan zanen gado da kuma haɗa nodes zuwa bayanin martaba;

Spot waldi: don takardar karfe wanda ba zai iya shiga ba tare da ƙusa ƙusa;

Stapling: na mahimmanci na biyu daga tsarin ra'ayi saboda raguwar juriya; ana amfani da shi don haɗa zanen gado don ƙarfafa shimfidar wurare;

Riveting: ana amfani da shi a cikin abubuwa masu ɗaukar nauyi tare da faffadan daɗaɗɗa; tare da kauri iri ɗaya, yana da juriya fiye da 30% idan aka kwatanta da walda; Hakanan yana da fa'idar buƙatar ƙarancin kuzari kuma baya canza tsarin kayan.

Adhesives na tsari: ana amfani da shi don ƙayyadaddun gilashin, a cikin kofa da haɗin gwiwa (tare da screwing), a cikin goyan bayan girgiza mai ɗaukar hoto (tare da riveting da waldi).

Majalisar

Bayan yin gyare-gyare, ana yin taro ta hanyar waldawar kayan aikin mutum-mutumi.

Ana yin ƙarewa ta hanyar niƙa da phosphating tare da cations 3 (Zn, Ni, Mn), wanda ke inganta mannewa na cataphoresis Layer ta hanyar tsomawa.

Ana yin zane-zane kamar yadda ga jikin karfe. Tuni a wannan mataki, farkon tsufa na wucin gadi ya faru, wanda aka kammala ta hanyar ƙarin magani mai zafi a 210 ° C na minti 30.