Man danko

Abubuwa

- Me ake amfani da man fetur?

- Menene dankon mai

- Nadi na injin mai bisa ga rarrabuwar SAE

- Zayyana man inji bisa ga ma'aunin API

- Kinematic da tsauri mai danko

- Halayen mai na mota

- Oil tushe da Additives

- Ma'adinai, roba da Semi-Synthetic man inji

- Wane danko mai ya fi dacewa don injin motar ku

- dumama injin da dankon mai

- Dankin man inji a yanayin aiki

- Abin da ke faruwa a lokacin da danko na man ya kasance sama da al'ada

- Abin da ke faruwa a lokacin da danko na man ya kasa al'ada

- Sakamakon

Dankin mai yana daya daga cikin mahimman sigogin man injin mota. Yawancin masu motoci sun ji game da wannan siga, sun ga alamar danko akan alamun mai, amma mutane kaɗan ne suka san ma'anar waɗannan haruffa da lambobi da abin da suke shafa. A cikin wannan labarin, za mu magana game da danko mai, danko tsarin nadi tsarin, da kuma yadda za a zabi da danko mai na mota engine.

Me ake amfani da man fetur?

Man fetur na mota yana ba da garantin daidaitaccen aiki na tsarin daban-daban. Ana amfani dashi don rage rikice-rikice, sanyi, mai mai, canja wurin matsa lamba zuwa sassa da sassan motar, cire kayan konewa. Yanayin aiki mafi wahala ga mai mota. Kada su rasa kaddarorin su tare da canje-canje nan take a cikin kayan zafi da na inji, ƙarƙashin tasirin iskar oxygen da abubuwa masu haɗari waɗanda aka kafa yayin ƙonewar man fetur bai cika ba.

Man yana haifar da fim ɗin mai a saman sassan shafa kuma yana rage lalacewa, yana ba da kariya daga tsatsa, kuma yana rage tasirin abubuwan da ke aiki da sinadarai da aka samu yayin aikin injin. Yin kewayawa a cikin crankcase, man yana kawar da zafi, cire samfuran lalacewa (kwayoyin ƙarfe) daga yankin lamba na sassan shafa, rufe rata tsakanin bangon Silinda da sassan rukunin piston.

Menene dankon mai

Danko shine mafi mahimmancin halayen man inji, wanda ya dogara da yanayin zafi. Kada man ya kasance dankowa sosai a lokacin sanyi ta yadda mai farawa zai iya juyar da crankshaft kuma famfon mai zai iya jefa mai cikin tsarin lubrication. A yanayin zafi mai zafi, man fetur bai kamata ya sami raguwar danko ba don ƙirƙirar fim ɗin mai tsakanin sassan shafa da kuma samar da matsa lamba mai mahimmanci a cikin tsarin.

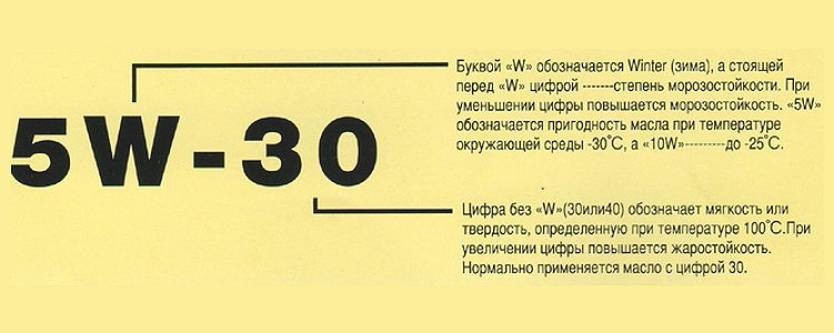

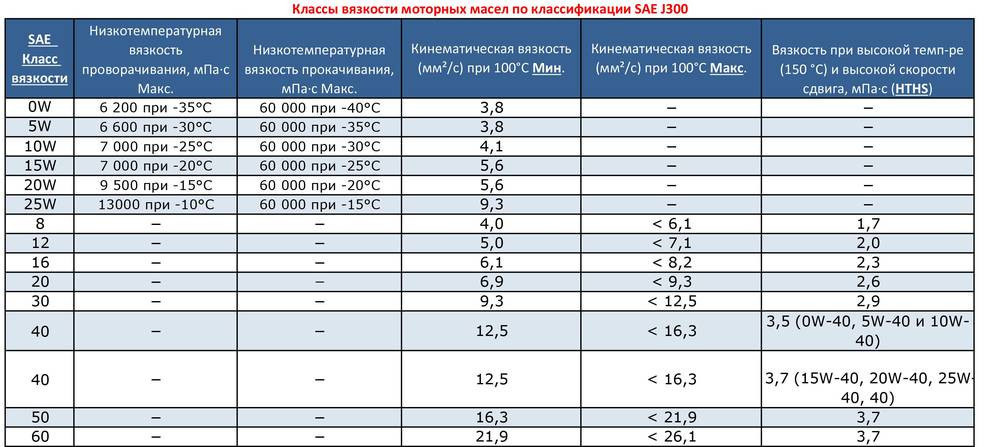

Nadi na injin mai bisa ga rarrabuwar SAE

Ƙungiyar SAE (American Society of Automotive Engineers) rarrabuwa tana kwatanta danko kuma ta ƙayyade a wane kakar za a iya amfani da mai. A cikin fasfo ɗin abin hawa, masana'anta suna tsara alamun da suka dace.

Mai bisa ga rarrabuwar SAE sun kasu zuwa:

- Winter: akwai wasiƙa akan alamar: W (hunturu) 0W, 5W, 10W, 15W, 20W, 25W;

- Lokacin rani - 20, 30, 40, 50, 60;

- Duk kakar: 0W-30, 5W-40, da dai sauransu.

Lambar da ke gaban harafin W a cikin injin man inji yana nuna ƙarancin zafinsa, watau yanayin zafin da injin mota da ke cike da wannan mai zai iya fara “sanyi”, kuma famfon mai zai zubar da mai ba tare da barazanar bushewa ba. daga sassan injin. Alal misali, don 10W40 mai, mafi ƙarancin zafin jiki shine -10 digiri (cire 40 daga lambar kafin W), kuma mahimmin zafin jiki wanda mai farawa zai iya fara injin shine -25 digiri (cire 35 daga lambar da ke gaban W). da W). Sabili da haka, ƙananan lamba a gaban W a cikin ƙirar mai, ƙananan zafin iska wanda aka tsara shi.

Lamba bayan harafin W a cikin injin injin man fetur yana nuna yanayin zafinsa, wato, mafi ƙarancin ɗanƙon mai da matsakaicin yanayin yanayin aikinsa (daga digiri 100 zuwa 150). Mafi girman lambar bayan W, mafi girman ɗanƙon man injin ɗin a yanayin yanayin aiki.

Matsakaicin zafin da injin motar motarka dole ne ya kasance da shi ga masana'anta ne kawai ya san shi, don haka ana ba da shawarar cewa ka bi ka'idodin masu kera motoci na man inji, waɗanda ke cikin umarnin motarka.

Ana ba da shawarar mai tare da maki daban-daban na danko don amfani a yanayin zafi daban-daban:

SAE 0W-30 - daga -30 ° zuwa + 20 ° C;

SAE 0W-40 - daga -30 ° zuwa + 35 ° C;

SAE 5W-30 - daga -25 ° zuwa + 20 ° C;

SAE 5W-40 - daga -25 ° zuwa + 35 ° C;

SAE 10W-30 - daga -20 ° zuwa + 30 ° C;

SAE 10W-40 - daga -20 ° zuwa + 35 ° C;

SAE 15W-40 - daga -15 ° zuwa + 45 ° C;

SAE 20W-40 - daga -10° zuwa +45°C.

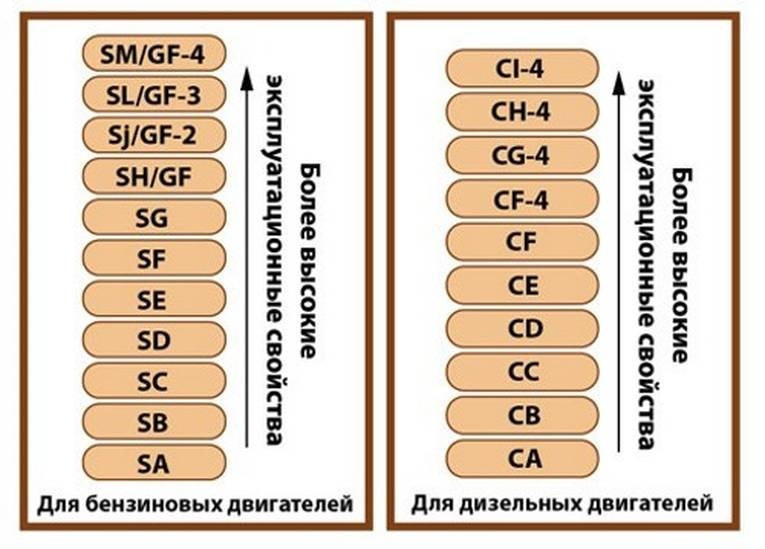

Zayyana man inji bisa ga ma'aunin API

Ma'auni na API (Cibiyar Man Fetur ta Amurka) ta ƙayyade inda ya kamata a yi amfani da mai. Ya ƙunshi haruffan Latin guda biyu. Harafin farko S yana nufin fetur, C na diesel. Harafi ta biyu ita ce ranar da aka kera motar.

Man gas:

- SC - motocin da aka samar kafin 1964;

- SD: motocin da aka samar tsakanin 1964 da 1968;

- SE - kwafin da aka samar a 1969-1972;

- SF - motoci da aka samar a cikin lokaci 1973-1988;

- SG - motocin da aka haɓaka a cikin 1989-1994 don aiki a cikin yanayi mai wahala;

- Sh - motoci da aka haɓaka a cikin 1995-1996 don yanayin aiki mai tsanani;

- SJ - kwafi, tare da ranar saki na 1997-2000, tare da mafi kyawun tanadin makamashi;

- SL - motoci, tare da farkon samarwa a 2001-2003, kuma tare da tsawon rayuwar sabis;

- SM - motoci da aka samar tun 2004;

- SL+ ya inganta juriya na iskar shaka.

Don injunan dizal:

- SV - motoci da aka samar kafin 1961, babban abun ciki na sulfur a cikin man fetur;

- SS - motoci da aka samar kafin 1983, suna aiki a cikin yanayi mai wuya;

- CD - motocin da aka ƙera kafin 1990, waɗanda dole ne suyi aiki a cikin yanayi mai wuya kuma tare da babban adadin sulfur a cikin man fetur;

- CE - motocin da aka kera kafin 1990 kuma suna da injin injin turbin;

- CF - motoci da aka samar tun 1990, tare da turbine;

- CG-4 - kwafin da aka samar tun 1994, tare da turbine;

- CH-4 - motoci tun 1998, bisa ga ka'idojin guba da aka karɓa a Amurka;

- KI-4 - motoci masu turbocharged tare da bawul na EGR;

- CI-4 plus - kama da na baya, a ƙarƙashin manyan ƙa'idodin guba na Amurka.

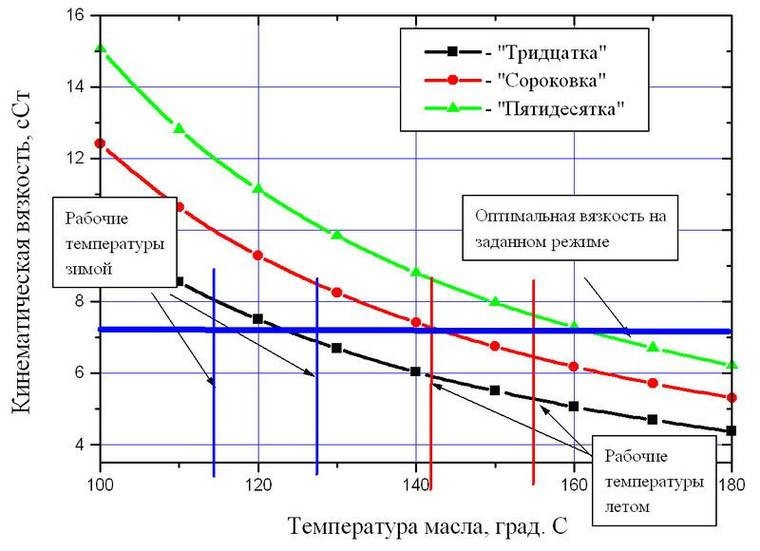

Kinematic da tsauri mai danko

Don ƙayyade ingancin man fetur, an ƙayyade kinematic da danko mai ƙarfi.

Dankowar Kinematic alama ce ta ruwa a al'ada (+40°C) da kuma yanayin zafi mai girma (+100°C). Ƙaddara ta amfani da viscometer capillary. Don ƙayyade shi, ana la'akari da lokacin da mai ke gudana a yanayin zafi da aka ba. Aunawa cikin mm2/sec.

Dynamic danko alama ce da ke ƙayyade halayen mai mai a cikin na'urar kwaikwayo ta gaske - na'urar viscometer na juyawa. Na'urar tana siminti na gaske lodi a kan injin, yin la'akari da matsa lamba a cikin layin da zazzabi na +150 ° C, kuma yana sarrafa yadda ruwan mai mai ya kasance, yadda dankon sa ke canzawa daidai a lokutan lodi.

Halayen mai na mota

- Ma'anar walƙiya;

- zuba batu;

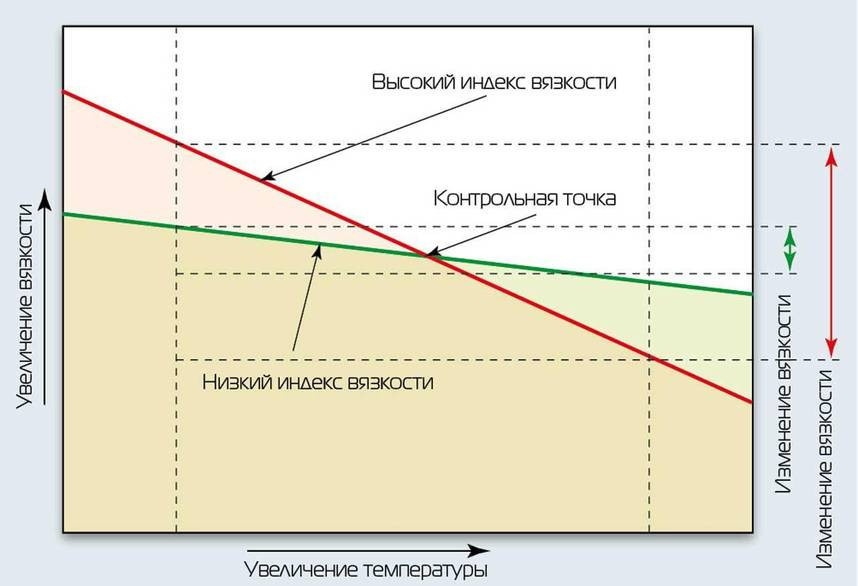

- index danko;

- lambar alkaline;

- lambar acid.

Ma'anar walƙiya wata ƙima ce da ke nuna kasancewar ɓangarorin haske a cikin mai, waɗanda ke ƙafe da ƙonewa da sauri, suna lalata ingancin mai. Matsakaicin filasha kada ya kasance ƙasa da 220°C.

Matsakaicin zube shine darajar da mai ke rasa ruwan sa. Yanayin zafin jiki yana nuna lokacin da paraffin crystallization da cikakken ƙarfafa mai.

ma'anar danko - yana kwatanta dogara da dankon mai akan canje-canjen zafin jiki. Mafi girman wannan adadi, mafi girman kewayon zafin aiki na mai. Kayayyakin da ke da ƙarancin ɗanƙoƙi kawai suna ƙyale injin yayi aiki tsakanin kunkuntar kewayon zafin jiki. Tun lokacin da suka yi zafi, sun zama ruwa mai yawa kuma suna daina shafawa, kuma idan sun sanyaya, suna yin kauri da sauri.

Lambar tushe (TBN) tana nuna adadin abubuwan alkaline (potassium hydroxide) a cikin gram ɗaya na man inji. Ƙungiyar ma'auni mgKOH/g. Yana nan a cikin ruwan motsa jiki a cikin nau'i na abubuwan da ke tarwatsawa. Kasancewar sa yana taimakawa wajen kawar da acid mai cutarwa da kuma yaƙar ajiya waɗanda ke bayyana yayin aikin injin. Bayan lokaci, TBN yana raguwa. Babban digo a cikin lambar tushe yana haifar da lalata da datti a cikin akwati. Babban mahimmanci wajen rage lambar tushe shine kasancewar sulfur a cikin man fetur. Don haka, man injin dizal, inda sulfur yake da yawa, yakamata ya sami TBN mafi girma.

Lambar acid (TAN) tana nuna kasancewar samfuran oxidation a sakamakon aiki na dogon lokaci da zafi mai zafi na injin injin. Ƙaruwar sa yana nuna raguwar rayuwar sabis na mai.

Oil tushe da Additives

Man fetur ɗin mota suna yin su ne da man tushe da ƙari. Additives wasu abubuwa ne na musamman waɗanda ake ƙarawa a cikin mai don inganta halayensa.

Mai tushe:

- ma'adinai;

- hydrocracking;

- Semi-synthetics (cakuda ruwan ma'adinai da synthetics);

- roba (ƙira da aka yi niyya).

A cikin mai na zamani, rabon additives shine 15-20%.

Dangane da manufar additives an raba su zuwa:

- kayan wanke-wanke da masu watsawa: ba sa ƙyale ƙananan ragowar (resins, bitumen, da dai sauransu) su manne tare kuma, suna da alkali a cikin abun da ke ciki, suna kawar da acid, ba sa barin sludge ajiya ya yi kauri;

- anti-wear - yana haifar da kariya mai kariya akan sassa na karfe kuma yana rage lalacewa ta hanyar shafa ta hanyar rage rikici;

- index - ƙara danko na man fetur a babban yanayin zafi, kuma a yanayin zafi kadan yana ƙara yawan ruwa;

- defoamers - rage samuwar kumfa (cakuda da iska da man fetur), wanda ke lalata zafi da kuma ingancin mai mai;

- gogayya gyare-gyare: rage coefficient na gogayya tsakanin karfe sassa.

Ma'adinai, roba da Semi-Synthetic man inji

Man shine cakuda hydrocarbons tare da takamaiman tsarin carbon. Za su iya haɗawa cikin dogayen sarƙoƙi ko reshe. Da tsayi da madaidaiciyar sarƙoƙin carbon, mafi kyawun mai.

Ana samun mai daga man fetur ta hanyoyi da yawa:

- hanya mafi sauƙi ita ce distillation na man fetur tare da hakar kaushi daga kayan mai;

- hanyar da ta fi rikitarwa - hydrocracking;

- ma fi hadaddun ne catalytic hydrocracking.

Ana samun mai na roba daga iskar gas ta hanyar ƙara tsawon sarƙoƙi na hydrocarbon. Ta wannan hanyar yana da sauƙi don samun dogon igiyoyi. "Synthetics" - mafi kyau fiye da ma'adinai mai, sau uku zuwa biyar. Babban koma bayansa shine tsadar sa sosai.

"Semi-synthetics" - cakuda ma'adinai da mai.

Wane danko mai ya fi dacewa don injin motar ku

Danko kawai da aka nuna a cikin littafin sabis ya dace da motarka. Duk sigogin injin ana gwada su ta hanyar masana'anta, an zaɓi man injin tare da la'akari da duk sigogi da yanayin aiki.

dumama injin da dankon mai

Lokacin da motar ta tashi, man injin yana sanyi kuma yana da danko. Sabili da haka, kauri na fim ɗin mai a cikin ramuka yana da girma kuma ƙimar juzu'i a wannan lokacin yana da girma. Idan injin ya yi zafi, man zai yi zafi da sauri ya fara aiki. Abin da ya sa masana'antun ba su bayar da shawarar nan da nan loading mota (farawa da motsi ba tare da high quality-dumi) a cikin tsananin sanyi.

Dankin man inji a yanayin aiki

Ƙarƙashin yanayin nauyi mai yawa, ƙimar juzu'i yana ƙaruwa kuma zafin jiki yana ƙaruwa. Saboda yawan zafin jiki, man zaitun yana raguwa kuma kauri na fim yana raguwa. Ƙididdigar haɗin kai yana raguwa kuma man ya yi sanyi. Wato, zafin jiki da kauri na fim sun bambanta tsakanin iyakokin da masana'anta suka ayyana sosai. Wannan yanayin ne zai ba da damar mai ya cika manufarsa da kyau.

Abin da ke faruwa a lokacin da danko na man ya kasance sama da al'ada

Idan danko ya fi na al'ada, koda bayan injin ya yi dumi, dankon mai ba zai ragu zuwa darajar da injiniyan ya ƙidaya ba. A ƙarƙashin yanayin kaya na al'ada, zafin injin zai tashi har sai danko ya dawo daidai. Saboda haka ƙarshe ya biyo baya: yawan zafin jiki na aiki yayin aiki na man injin da ba a zaɓa ba zai ci gaba da ƙaruwa, wanda ke ƙaruwa da lalacewa na sassan injin da taro.

Ƙarƙashin nauyi mai nauyi: Lokacin gaggawar gaggawa ko a kan dogon tudu mai tsayi, zafin injin zai ƙara ƙaruwa kuma yana iya wuce yanayin zafin da mai ke kula da kayan aikinsa. Zai oxidize da varnish, soot da acid za su samar.

Wani rashin lahani na man da ke da ɗan ɗorewa shi ne yadda wasu ƙarfin injin ɗin za su yi asara saboda yawan ƙarfin bututun da ke cikin na'urar.

Abin da ke faruwa a lokacin da danko na man ya kasa al'ada

Dankin mai da ke ƙasa da al'ada ba zai kawo wani abu mai kyau ga injin ba, fim ɗin mai a cikin ramuka zai kasance ƙasa da al'ada, kuma kawai ba zai sami lokaci don cire zafi daga yankin gogayya ba. Don haka, a waɗannan wuraren da ake ɗaukar nauyi, man zai ƙone. tarkace da guntun karfe tsakanin fistan da silinda na iya sa injin ya kama.

Man da ya yi kauri a cikin sabon injin, idan gibin bai yi nisa ba, zai yi aiki, amma idan injin ya daina sabo kuma gibin ya karu da kansu, aikin kona man zai yi sauri.

Fim na bakin ciki na mai a cikin ramuka ba zai iya samar da matsawa na al'ada ba, kuma wani ɓangare na kayan konewa na man fetur zai shiga cikin mai. Saukowar wutar lantarki, zafin aiki yana ƙaruwa, tsarin lalata da ƙonewar mai yana haɓaka.

Ana amfani da irin wannan mai a cikin kayan aiki na musamman, wanda aka tsara hanyoyin da aka tsara don yin aiki tare da waɗannan mai.

Sakamakon

Mai da darajar danko iri ɗaya, yana da halaye iri ɗaya, wanda kamfani ke samarwa wanda aka haɗa a cikin "Big Five", kuma yana da tushe iri ɗaya, a matsayin mai mulkin, ba sa shiga cikin mu'amala mai ƙarfi. Amma idan ba ka so manyan matsaloli, shi ne mafi alhẽri a ƙara fiye da 10-15% na jimlar girma. A nan gaba, bayan cika man fetur, yana da kyau a canza man gaba daya.

Kafin zabar mai, yakamata ku gano:

- ranar da aka kera motar;

- kasancewar ko rashin tilastawa;

- kasancewar injin turbin;

- yanayin aiki injin (birni, kashe-hanya, wasanni gasa, sufurin kaya);

- mafi ƙarancin yanayin yanayi;

- matakin lalacewar injin;

- matakin dacewa da injin da mai a cikin motar ku.

Don fahimtar lokacin da za a canza man fetur, kuna buƙatar mayar da hankali kan takardun don mota. Ga wasu motocin, lokutan suna da tsawo (kilomita 30-000). Ga Rasha, la'akari da ingancin man fetur, yanayin aiki da yanayin yanayi mai tsanani, maye gurbin ya kamata a yi bayan 50 - 000 km.

Ana buƙatar lokaci-lokaci don sarrafa inganci da adadin mai. Kula da kamannin su. Mizanin abin hawa da sa'o'in injin (lokacin gudu) bazai dace ba. Yayin da yake cikin cunkoson ababen hawa, injin yana aiki a yanayin zafi mai ɗorewa, amma odometer baya juyi (motar ba ta tuƙi). A sakamakon haka, motar ta yi tafiya kadan, kuma injin ya yi aiki sosai. A wannan yanayin, yana da kyau a canza mai a baya, ba tare da jiran nisan da ake buƙata akan odometer ba.