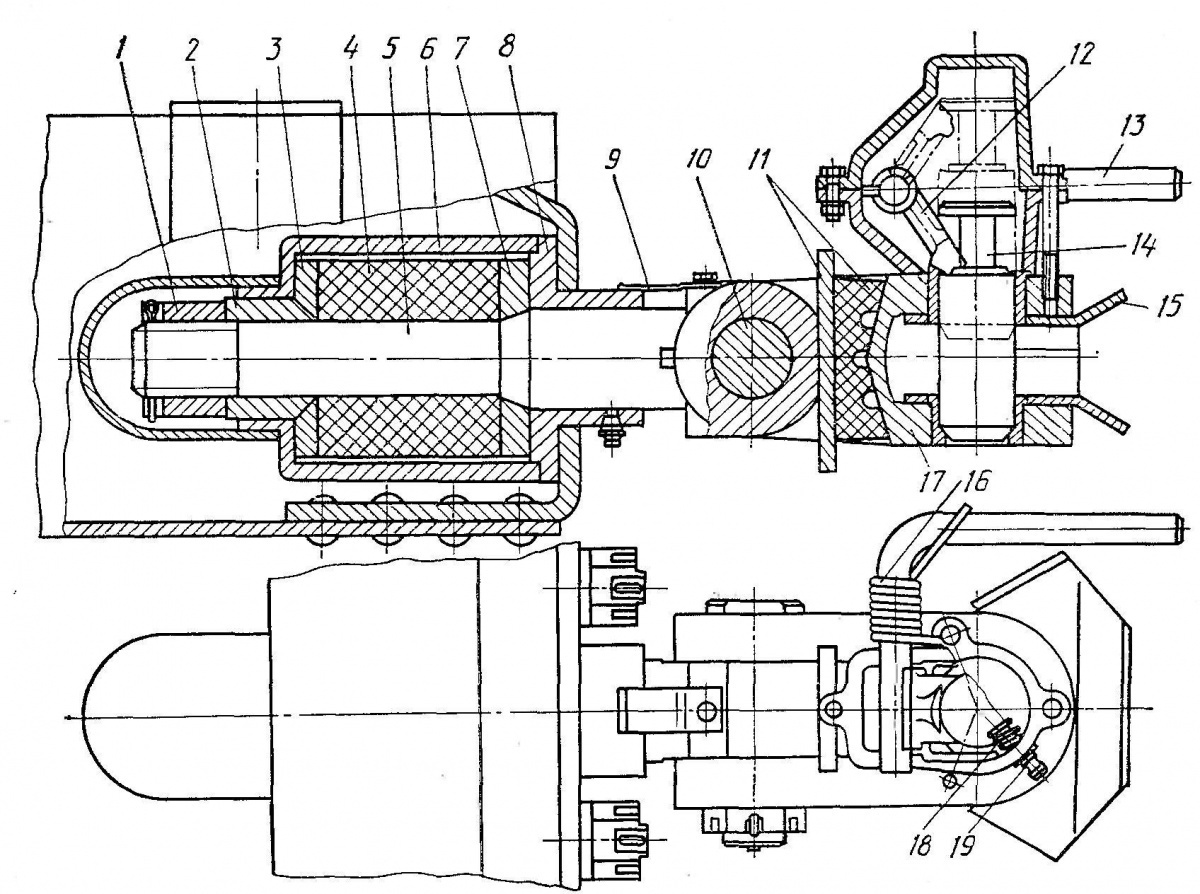

Na'urorin haɗakarwa na tarakta

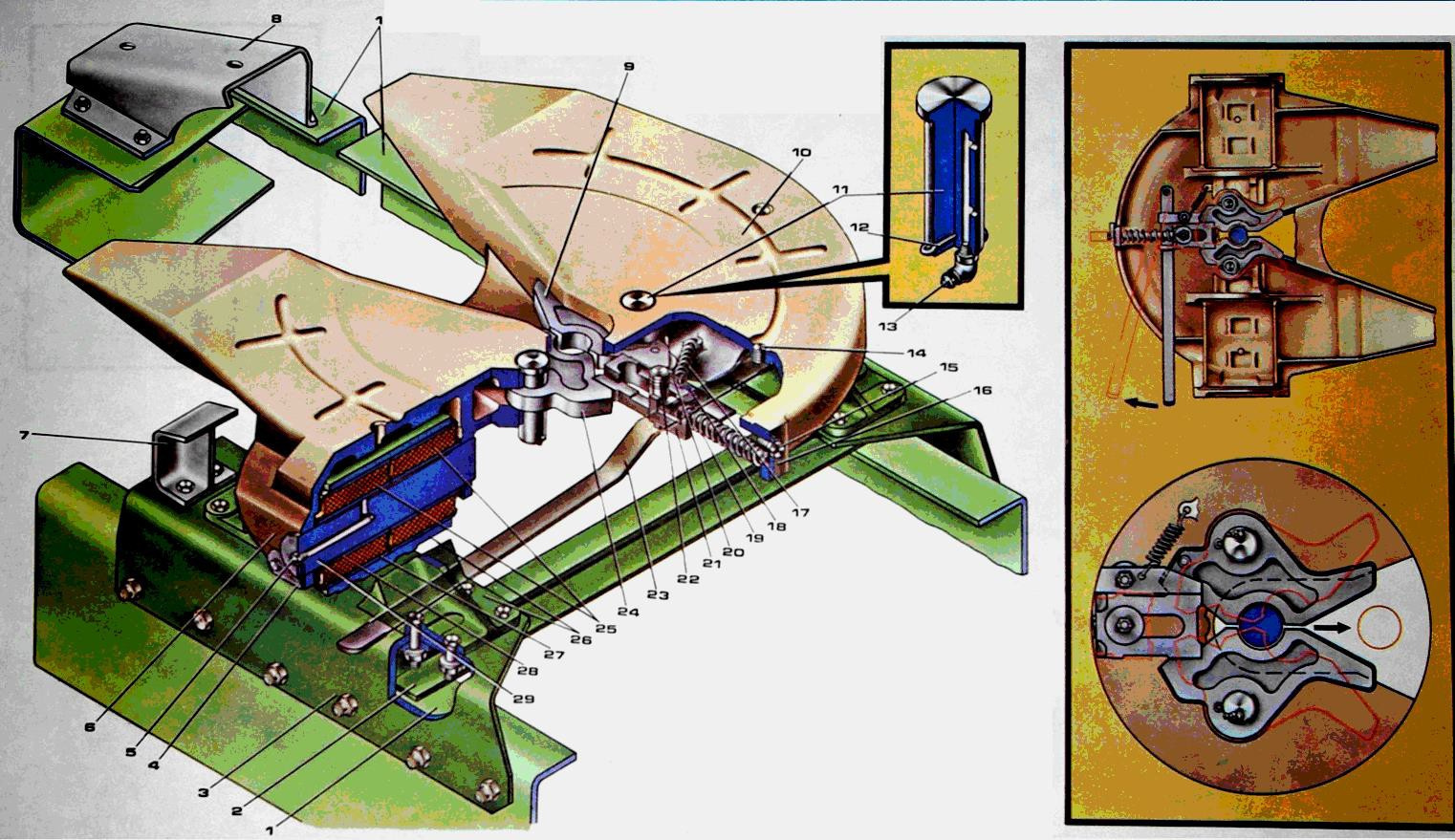

Ma'amalar motsi da wutar lantarki na hanyoyin sufuri na jirgin kasa tare da tirela ana aiwatar da su ta hanyar na'urar ja (Fig. 1).

Na'urorin haɗakarwa (TSU) na tarakta sun ƙunshi na'ura mai cirewa mai cirewa, abin damping da gyara sassa.

Dangane da tsarin tsarin haɗin kai wanda za a iya cirewa, an raba na'urori masu ja zuwa:

- crochet (biyu na ƙugiya da madaukai),

- fil (biyu na fil- madaukai),

- ball (biyu-madauki biyu).

Abun damping yana amfani da maɓuɓɓugan murɗa, abubuwan roba da maɓuɓɓugan zobe.

Mafi yaɗuwa akan jiragen ƙasa masu ɗauke da tirela sune ƙugiya-da-haɗin gwiwa.

Hoto 1 - Na'urorin haɗi na tarakta: 1 - mai karɓa; 2 - jiki na actuator; 3 - lever mai gyarawa; 4 - murfin sarki; 5 - tsarin murfin gidaje; 6 - bazara; 7 - firam; 8 - kayan aiki; 9 - fil na tsakiya; 10 - sirdi na tsakiyar sarki; 11 - makulli; 12 - akwatin fuse; 13 - fuse ta atomatik decoupling; 14 - hular kwaya na ƙugiya na tsarin ƙarshe; 15 - goro; 16 - jiki na na'urar ja; 17- mai dakatar da na'urar ja; 18 - murfin na'urar ja; 19 - ƙugiya kulle ratchet; 20 - latsa; 21 - ku

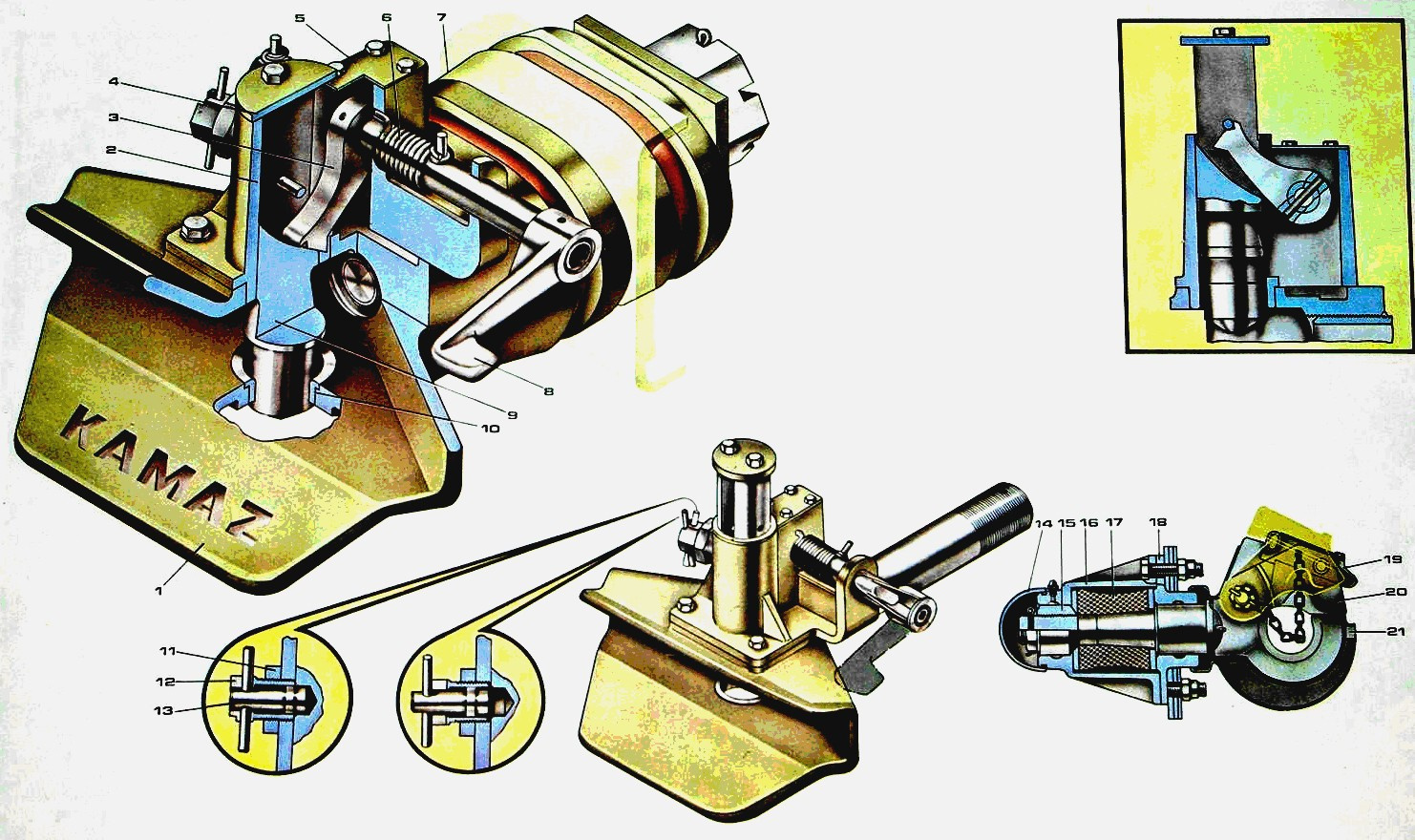

Ƙimar ƙugiya na motar KamaZ-5320 (Fig. 2) ya ƙunshi ƙugiya 2, sandar wanda ya ratsa cikin ramukan da ke cikin memba na giciye na baya na firam, wanda ke da ƙarin ƙarfafawa. An saka sandar a cikin wani katon cylindrical jiki 15, an rufe shi a gefe guda da hular kariya 12, a daya gefen kuma ta hanyar casing 16. Abun roba na roba (shock absorber) 9, wanda ke sassaukar nauyin girgiza lokacin da za a tada mota daga motar. wuri tare da tirela daga wuri kuma lokacin tuƙi akan hanya mara kyau, yana tsakanin masu wanki biyu 13 da 14. Na 10 yana ba da matsi na farko na tsayawar roba 9. A kan shaft 3 da ke wucewa ta ƙugiya, tare da toshe ta hanyar ƙugiya. pawl 4, wanda ke hana madauki mai haɗawa daga nesa daga ƙugiya.

Hoto 2 - ƙugiya mai ja: 1 - mai; 2 - ƙugiya; 3 - axis na latch ƙugiya; 4 - ruwan zafi; 5 - ratchet axis; 6 - tukwane; 7 - kwaya; 8 - wani nau'i na nau'i na katako; 9 - kashi na roba; 10 - ƙugiya-kwaya; 11 - tukwane; 12 - murfin kariya; 13, 14 - masu wanki; 15 - jiki; 16 - murfin gidaje

Don buga tarakta tare da tirela:

- birki tirela tare da tsarin birki na filin ajiye motoci;

- bude latch na ƙugiya;

- shigar da mashin ɗin tirela ta yadda idon da aka ƙulle ya kasance daidai da ƙugiya mai ja da abin hawa;

- a hankali ɗaga motar baya har sai ƙugiya mai ja ta tsaya a kan abin tirela;

- sanya madauki na ja a kan ƙugiya mai ja, rufe latch kuma gyara shi da ratchet;

- toshe tirela a cikin soket ɗin abin hawa;

- haɗa kayan aikin bututu na tsarin pneumatic na tirela tare da daidaitattun kayan aiki na tsarin pneumatic na mota;

- haɗa tirela zuwa mota tare da kebul na aminci ko sarkar;

- bude bawuloli na kashe-kashe don motar pneumatic na tsarin birki na tirela da aka sanya akan abin hawa (waya guda ɗaya ko da'ira biyu);

- birki tirela da tsarin birki na parking.

Ƙaƙwalwar ƙira ta bambanta da ƙirar ƙugiya na tsarin tsinkewa.

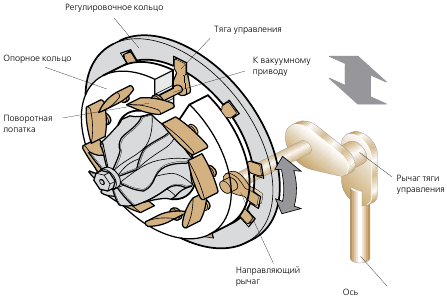

Na'urar da za a iya cirewa-haɗe-haɗe na pivot hinge (Fig. 3) ya ƙunshi cokali mai yatsa 17 ("mai karɓa"), pivot 14 da ƙugiya. Labulen da aka sanya a cikin jiki ya ƙunshi maƙalli 13, shaft, bel 12 da kuma kayan aiki mai kaya 16. An haɗa cokali mai yatsa zuwa sanda 5 ta hanyar shaft 10, wanda ke ba da sassaucin mahimmanci na watsawa a cikin jirgin sama na tsaye. A cikin 'yanci, tsarin haɗin haɗin gwiwa yana riƙe da tasha ta roba 11 da sandar bazara 9.

Hoto 3 - Matsakaicin juyawa: 1 - kwaya; 2 - hannun rigar jagora; 3, 7 - flanges; 4 - kashi na roba; 5 - sanda; 6 - jiki; 8 - murfin; 9 - bazara; 10 - sandar axis; 11 - buffer; 12 - madauri; 13 - rike 14 - sarki; 15 - madauki jagora; 16, 18 - maɓuɓɓugan ruwa; 17 - cokali mai yatsa; 19- fusa

Kafin hada tarakta tare da tirela, latch ɗin yana "cocked" tare da rike 13, yayin da fil 14 yana riƙe da matsi 12 a matsayi na sama. Spring 16 an matsa. Ƙarshen madaidaicin madaidaicin na kingpin 14 yana fitowa wani yanki daga saman strut 17 na cokali mai yatsa. Madaidaicin madaidaicin tirela yana shiga jagorar cokali mai yatsa 15 lokacin da aka saukar da labule. Madaidaicin madauri 12 yana sakin ƙugiya ta tsakiya 14, wanda, ƙarƙashin aikin nauyi da bazara 16, yana motsawa zuwa ƙasa, yana yin ƙugiya. Faduwar kingpin 14 daga ramin juzu'i yana hana fuse 19. Lokacin da aka haɗa shi, madaidaicin madauki ya shiga cokali mai yatsu na TSU ya danna ƙasa mai siffar mazugi na kingpin 14, wanda ke taimakawa wajen ɗaga shi a ɗan gajeren nesa Ku saki takalmi (yoke) 12 daga sarki.

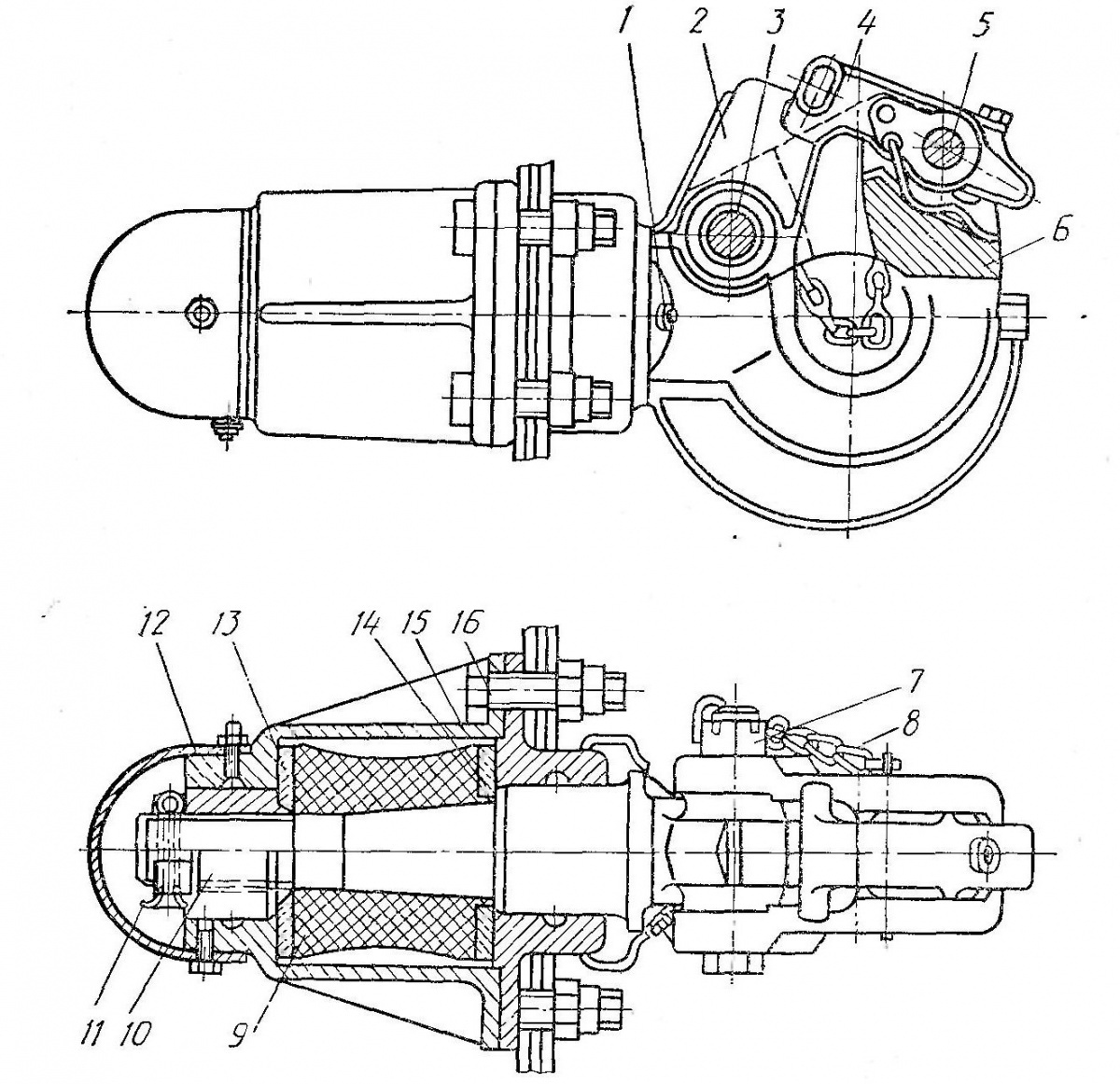

Ƙarfin wutar lantarki da hulɗar motsi na hanyoyin sufuri na sirdi na titin jirgin yana samuwa ta hanyar haɗakarwa ta biyar (Fig. 4).

Hoto 4 - Taraktan motar: 1 - chassis abin hawa; 2 - memba na giciye na na'urar sirdi; 3 - goyon bayan sirdi; 4 - farantin gindi; 5 - mai; 6 - gefen idanu na sirdi; 7 - shingen sirdi; 8 - na'urar zamewa sirdi; 9 - soso na hagu; 10 - ɗaukar saman farantin tushe; 11 - yatsa mai soso; 12 - tukwane; 13 - mai; 14 - fil don haɗa hannu; 15 - axis na shingen tsaro; 16 - fuse don cirewa ta atomatik na hanyar haɗin gwiwa; 17 - Makullin ratchet na bazara; 18 - axis na kulle dunƙule dunƙule; 19 - kulle cam spring; 20 - karen da aka kama; 21 - kulle dunƙule; 22 - axis na kulle dunƙule; 23 - rike da kulle kulle; 24 - soso dama; 25 - hinge; 26 - goyon baya; 27 - hannun riga; 28 - hannun riga na ciki; 29 - axis na hanji

Ana amfani da haɗin haɗin ƙafa na biyar don haɗawa da kuma cire haɗin tarakta daga babban tirela, da kuma canja wurin babban kaya mai mahimmanci daga motar motar zuwa abin hawa da kuma raguwa daga tarakta zuwa babban tirela.

Na'urar tana ba da haɗin kai ta atomatik da kwancen tarakta tare da ƙaramin tirela. Tirela tana sanye da farantin tushe tare da pivot (Fig. 5). An daidaita diamita na saman aiki na fil ɗin sarki kuma daidai yake da 50,8 ± 0,1 mm.

Hoto na 5 - Semi-trailer kingpin don haɗawa da tarakta ta biyar hadaddiyar dabara

Hanya na biyar (Fig. 4) an ɗora shi a kan firam ɗin tarakta ta hanyar amfani da maƙallan biyu 3 da aka haɗa ta hanyar mamba na giciye 2. Ƙaƙƙarfan 3 suna da kullun da aka shigar da sirdi a kan ta amfani da hinges biyu 25, wanda shine farantin tushe. 10 tare da protrusion gefe biyu 6.

Idanun gefen 6 na sirdi suna da alaƙa da gatari 29 na hinges 25, waɗanda ke ba da takamaiman karkata ga sirdi a cikin jirgin sama mai tsayi. Axles 29 yana jujjuya da yardar kaina a cikin bushings na roba-karfe 27 da 28. Wannan bayani yana ba da wani ɗan gajeren niyya na Semi-trailer yayin motsi, kazalika da ɗan karkata karkatacciya (har zuwa 3º), wanda ke nufin yana rage ƙarfin kuzarin da aka watsa ta hanyar. trailer Semi-trailer zuwa firam ɗin tarakta. Shafts 29 ana kiyaye su daga motsin axial ta hanyar kulle faranti 4. Ana sanya mai 5 akan shaft kuma an yi tasha don samar da mai ga roba da bushing karfe 27.

A ƙarƙashin farantin tushe 10 na wurin zama akwai hanyar haɗawa. Ya ƙunshi hannaye guda biyu 9 da 24 ("sponges"), makullin kulle 21 tare da tushe da bazara 19, latch tare da bazara 17, lever mai buɗewa 23 da fis ɗin cirewa ta atomatik 16 gyarawa akan farantin tushe 10. ta amfani da fil 11 kuma ana iya jujjuya su a kusa da su, ɗaukar matsananciyar matsayi guda biyu (buɗe ko rufe). Makullin kulle 21 kuma yana da matsananciyar matsayi guda biyu: na baya - an rufe hannayen hannu, gaba - hannaye suna buɗe. Ruwan bazara 19 na sanda yana hana motsi na rike 21 zuwa matsayi na gaba. Makullin dunƙule dunƙule 21 abuts da kai fashe mashaya 16. Don haka.

An ɗora sandar fusible 16 akan axis 15 tare da yiwuwar jujjuyawarta don gyarawa ko sassauta sandar.

Kafin haɗa tarakta zuwa tirela, an saita shingen aminci na saki ta atomatik zuwa matsayin “buɗe”, wanda ke fitar da sandar mai ɗaukar hoto.

Don buga tarakta tare da ƙaramin tirela, juya madaidaicin iko gaba zuwa hanyar tafiyar abin hawa. A wannan yanayin, za a kulle makullin kulle a matsayi na gaba tare da latch. Direba yana saita tarakta ta hanyar da ƙaramin tirela kingpin ya ratsa tsakanin ƙusoshin kujera da kuma ƙara tsakanin ƙusoshin. Tun lokacin da hannun ya shiga cikin wuri a cikin matsayi na cocked, lokacin da aka saka sarki a cikin tsagi na hannayen hannu, hannayen suna buɗewa.

Ana sakin dunƙulewa daga gyare-gyare ta hanyar latch, yana tsayawa tare da bayansa a kan riko kuma yana riƙe su a cikin buɗewa. Tare da ƙarin motsi na ɓangaren baya na tarakta, kingpin yana aiki a kan hannayen hannu ta hanyar da za su rufe, da kuma rike, a ƙarƙashin aikin bazara, ya shiga cikin raƙuman angular na hannayen hannu kuma ya mamaye matsayi na baya, wanda ya kasance a baya. yana tabbatar da amintaccen kullewa. Bayan kullewa ya faru, dole ne a gyara sandar farko ta hanyar juya madaidaicin fuse mai buɗewa zuwa matsayin "kulle".

Don fara motsi tare da ƙaramin tirela, direba dole ne: ɗaga rollers (ko cylinders) na na'urar tallafi na Semi-trailer; haɗa da shugabannin tsarin pneumatic na tarakta da ƙananan tirela; haɗa wayoyin lantarki; sallamar tirelar parking birki

Kafin kwance layin dogo, direban ya birki na'urar tirela mai karamin tirela tare da tsarin birki na ajiye motoci, yana saukar da rollers (ko cylinders) na na'urar da ke goyan baya, ya cire haɗin kan na'urar haɗin kai na tsarin pneumatic da matosai na igiyoyin lantarki.

Don cirewa, ya zama dole a sake jujjuya mashaya fuse da lever mai sarrafawa, bayan haka, a cikin kayan aiki na farko, sannu a hankali matsar da tarakta gaba. Tun da za a matsar da trunnion zuwa matsayi na gaba kuma a kulle shi da ƙugiya, sarkin tirela zai fito da yardar rai daga hannun masu nadawa.

Don ƙara ƙarfin ɗaukar nauyin jirgin ƙasa, ana amfani da gajerun na'urori masu haɗawa da telescopic, ka'idar aiki wanda ya dogara ne akan rage nisa tsakanin tarakta da tirela yayin motsi na rectilinear da haɓaka shi lokacin yin kusurwa da motsa jiki.

Haɓaka ƙarfin ɗaukar nauyin jiragen kasa na hanya yana da alaƙa da haɓakar adadin gatari da tsayin su duka. Duk da haka, wannan yana haifar da tabarbarewar motsa jiki na hanyar jirgin kasa da kuma saurin lalacewa ta taya.

Yin amfani da axles na ƙafa da ƙafafu yana rage waɗannan kurakuran. Suna da sauƙi a cikin ƙira kuma suna buƙatar ƙananan samarwa da farashin kulawa.

A cikin tireloli biyu da uku-uku, axle na baya yana jujjuyawa a ƙarƙashin aikin sassan sassan halayen hanyar zuwa ƙafafunsa lokacin juyawa.

Hannun axles suna ƙara tsayin lodi da tsakiyar nauyi na ƙaramin tirela. Saboda haka, axles tare da ƙafafu masu daidaita kansu sun zama tartsatsi.