Crankshaft matsayin firikwensin

Abubuwa

Firikwensin crankshaft yana ba da iko daga injin ECU na matsayi na ɓangaren injin da ke da alhakin aiwatar da tsarin allurar mai. Lokacin da DPKV ya kasa, an gano shi tare da taimakon gwaje-gwaje na musamman da ke aiki akan ka'idar ohmmeter. A yayin da juriya na yanzu ke ƙasa da ƙimar ƙima, mai sarrafawa zai buƙaci maye gurbinsa.

Menene alhakin kuma ta yaya firikwensin crankshaft ke aiki?

Firikwensin matsayi na crankshaft yana ƙayyade daidai lokacin da ya kamata a aika mai zuwa silinda na ingin konewa (ICE). A cikin zane-zane daban-daban, DPKV yana da alhakin sarrafa daidaita daidaiton kayan aikin mai ta hanyar injectors.

Ayyukan firikwensin crankshaft shine yin rajista da watsa bayanai masu zuwa zuwa kwamfutar:

- auna matsayi na crankshaft;

- lokacin pistons sun wuce BDC da TDC a cikin silinda na farko da na ƙarshe.

Na'urar firikwensin PKV yana gyara alamun masu zuwa:

- yawan man fetur mai shigowa;

- lokacin samar da man fetur;

- kusurwar camshaft;

- lokacin kunna wuta;

- lokacin da tsawon lokacin aiki na bawul ɗin adsorption.

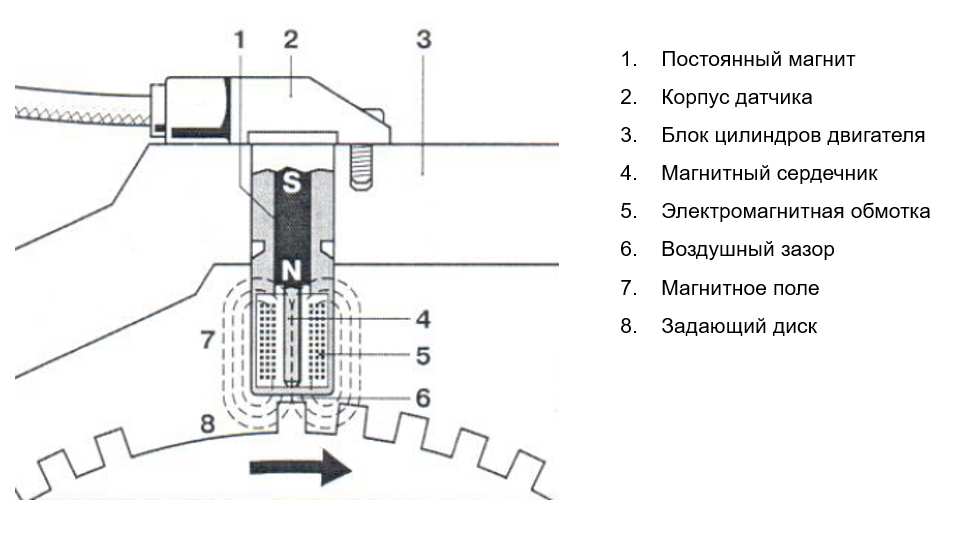

Ka'idar aiki na firikwensin lokaci:

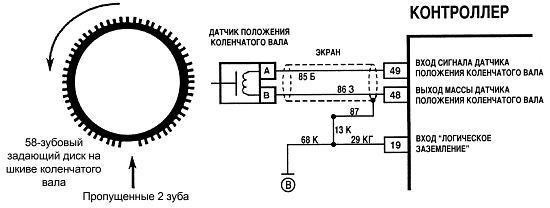

- A crankshaft sanye take da faifai tare da hakora (farawa da sifili). Lokacin da taron ya juya, filin maganadisu yana karkata zuwa hakora daga firikwensin PKV, yana aiki da shi. Ana yin rikodin canje-canje a cikin nau'in bugun jini kuma ana watsa bayanan zuwa kwamfutar: ana auna matsayin crankshaft da lokacin da pistons ke wucewa ta sama da ƙasa matattu cibiyoyin (TDC da BDC).

- Lokacin da sprocket ya wuce firikwensin saurin crankshaft, yana canza nau'in karatun haɓakawa. A saboda wannan dalili, ECU tana ƙoƙarin dawo da aikin yau da kullun na crankshaft.

- Dangane da bugun jini da aka karɓa, kwamfutar da ke kan jirgin tana aika sigina zuwa tsarin abin hawa da ake buƙata.

Farashin DPKV

Tsarin firikwensin Crankshaft:

- wani akwati na aluminum ko filastik siffar silindical tare da wani abu mai mahimmanci, ta inda ake aika sigina zuwa kwamfutar;

- kebul na sadarwa (magnetic circuit);

- rukunin tuki;

- sealant;

- iska;

- madaurin hawan injin.

Table: Nau'in firikwensin

| Имя | Description |

| Magnetic firikwensin

| Na'urar firikwensin ya ƙunshi maganadisu na dindindin da iska ta tsakiya, kuma wannan nau'in mai sarrafawa baya buƙatar keɓantaccen wutar lantarki. Na'urar lantarki mai haɓakawa tana sarrafa ba kawai matsayi na crankshaft ba, har ma da sauri. Yana aiki tare da ƙarfin lantarki da ke faruwa lokacin da haƙori na ƙarfe (tag) ya wuce ta filin maganadisu. Wannan yana haifar da bugun sigina wanda ke zuwa ECU. |

| Na'urar haska bayanai mai gani

| Firikwensin gani ya ƙunshi mai karɓa da LED. Yin hulɗa tare da faifan agogo, yana toshe kwararar gani da ke wucewa tsakanin mai karɓa da LED. Mai watsawa yana gano katsewar haske. Lokacin da LED ɗin ya wuce ta wurin tare da hakora da suka sawa, mai karɓa yana amsa bugun bugun jini kuma yana aiki tare da ECU. |

| Hall firikwensin

| Tsarin firikwensin ya haɗa da:

A cikin firikwensin crankshaft na Hall, halin yanzu yana gudana yayin da yake gabatowa wurin sauya yanayin maganadisu. Da'irar filin ƙarfin yana buɗewa lokacin wucewa ta wuraren da hakora da suka lalace kuma ana watsa siginar zuwa sashin sarrafa injin lantarki. Yana aiki daga tushen wutar lantarki mai zaman kansa. |

Ina firikwensin yake wurin?

Wurin firikwensin matsayi na crankshaft: kusa da faifai tsakanin madaidaicin juzu'i da ƙugiya. Don haɗin kai kyauta zuwa cibiyar sadarwar kan jirgin, an samar da kebul na 50-70 cm tsayi, wanda akwai masu haɗawa don maɓalli. Akwai masu sarari akan sirdi don saita tazarar 1-1,5mm.

Alamomi da sanadin rashin aiki

Alamomin raunin DPKV:

- injin ba ya farawa ko tsayawa ba tare da bata lokaci ba;

- babu tartsatsi;

- Fashewar ICE na faruwa lokaci-lokaci a ƙarƙashin kaya masu ƙarfi;

- Gudun aiki mara ƙarfi;

- An rage ƙarfin injin da motsin abin hawa;

- lokacin da ake canza yanayin, canji na kwatsam na adadin juyin yana faruwa;

- duba hasken injin akan dashboard.

Alamun suna nuna dalilai masu zuwa da yasa na'urar firikwensin PCV na iya zama kuskure:

- gajeriyar da'ira tsakanin jujjuyawar iska, yiwuwar murguda sigina game da matsayin fistan a BDC da TDC;

- kebul ɗin da ke haɗa DPKV zuwa ECU ya lalace - kwamfutar da ke kan jirgin ba ta karɓar sanarwar da ta dace;

- lahani na hakora (scuffs, kwakwalwan kwamfuta, fasa), injin bazai fara ba;

- Shigar da abubuwa na waje tsakanin ɗigon haƙori da counter ko lalacewa yayin aiki a cikin injin injin yakan haifar da rashin aiki na DPKV.

Matsalolin fara injin

Bambance-bambancen rashin aiki na firikwensin crankshaft wanda ke shafar aikin injin konewa na ciki:

- Inji baya farawa. Lokacin da aka kunna maɓallin kunnawa, mai kunnawa yana juya injin kuma fam ɗin mai yana hus. Dalilin shi ne cewa injin ECU, ba tare da samun sigina daga firikwensin matsayi na crankshaft ba, ba zai iya ba da umarni daidai ba: akan wanne na silinda zai fara da wanda zai buɗe bututun ƙarfe.

- Injin yana zafi har zuwa wani zafin jiki kuma yana tsayawa ko baya farawa cikin tsananin sanyi. Akwai dalili guda ɗaya kawai - microcrack a cikin iskar firikwensin PKV.

M aiki na inji a daban-daban halaye

Wannan yana faruwa ne lokacin da DPKV ya gurɓata, musamman lokacin da guntun ƙarfe ko mai ya shiga ciki. Ko da ɗan ƙaramin tasiri akan magnetic microcircuit na firikwensin lokaci ya canza aikinsa, saboda counter ɗin yana da hankali sosai.

Kasancewar fashewar motar tare da karuwar kaya

Dalili na yau da kullum shine gazawar mita, da kuma microcrack a cikin iska, wanda ke lanƙwasa a lokacin girgiza, ko fashewa a cikin gidaje, wanda danshi ya shiga.

Alamomin bugun inji:

- cin zarafi da santsi na tsarin konewa na cakuda man fetur-iska a cikin silinda na injin konewa na ciki;

- tsalle akan tsarin mai karɓa ko shayewa;

- gazawa;

- a sarari raguwa a cikin ikon inji.

Rage ƙarfin injin

Ƙarfin injin yana faɗuwa lokacin da ba a ba da cakuda man-iska cikin lokaci ba. Abin da ke haifar da rashin aiki shine ɓarkewar abin da ke ɗaukar girgizawa da kuma ƙaurawar tauraro mai haƙori dangane da juzu'in. Hakanan an rage ƙarfin injin saboda lalacewar iska ko gidaje na mitar matsayi na crankshaft.

Yadda za a duba firikwensin crankshaft da kanka?

Kuna iya bincika lafiyar DPKV da kansa ta amfani da:

- ohmmeter;

- oscillograph;

- hadaddun, ta amfani da multimeter, megohmmeter, gidan wuta na cibiyar sadarwa.

Muhimmancin sanin

Kafin maye gurbin na'urar aunawa, ana kuma ba da shawarar yin cikakken bincike na kwamfuta na injin konewar ciki. Sa'an nan kuma ana gudanar da bincike na waje, kawar da gurɓatawa ko lalacewar inji. Kuma kawai bayan haka sun fara ganowa tare da na'urori na musamman.

Dubawa tare da ohmmeter

Kafin ci gaba da ganewar asali, kashe injin kuma cire firikwensin lokaci.

Umurnin mataki-mataki don nazarin DPKV tare da ohmmeter a gida:

- Sanya ohmmeter don auna juriya.

- Ƙayyade matakin juriya na magudanar ruwa (taba gwajin gwajin zuwa tashoshi kuma a buga su).

- Ƙimar da aka yarda da ita ita ce daga 500 zuwa 700 ohms.

Yin amfani da oscilloscope

Ana duba firikwensin matsayi na crankshaft tare da injin yana gudana.

Algorithm na ayyuka ta amfani da oscilloscope:

- Haɗa mai gwadawa zuwa mai ƙidayar lokaci.

- Gudanar da shirin a kan kwamfutar da ke kan allo wanda ke kula da karatu daga na'urar lantarki.

- Wuce wani ƙarfe abu a gaban crankshaft firikwensin sau da yawa.

- Multimeter yana da kyau idan oscilloscope ya amsa motsi. Idan babu sigina akan allon PC, ana bada shawara don aiwatar da cikakken ganewar asali.

Cikakken dubawa

Don aiwatar da shi, dole ne ku sami:

- megger;

- gidan wuta na cibiyar sadarwa;

- inductance mita;

- voltmeter (zai fi dacewa dijital).

Algorithm na ayyuka:

- Kafin fara cikakken dubawa, dole ne a cire firikwensin daga injin, a wanke sosai, a bushe, sannan a auna. Ana yin shi ne kawai a dakin da zafin jiki, don haka alamun sun fi dacewa.

- Na farko, ana auna inductance na firikwensin (inductive coil). Kewayon ma'auni na ƙididdiga na aiki ya kamata ya kasance tsakanin 200 zuwa 400 MHz. Idan ƙimar ta bambanta sosai da ƙayyadaddun ƙimar, da alama firikwensin ya yi kuskure.

- Na gaba, kuna buƙatar auna juriya na rufewa tsakanin tashoshi na nada. Don wannan, ana amfani da megohmmeter, saita ƙarfin fitarwa zuwa 500 V. Zai fi kyau a aiwatar da hanyar auna sau 2-3 don samun ƙarin cikakkun bayanai. Ƙimar juriya da aka auna dole ne ta zama aƙalla 0,5 MΩ. In ba haka ba, ana iya ƙayyade gazawar insulation a cikin nada (ciki har da yiwuwar gajeriyar kewayawa tsakanin juyi). Wannan yana nuna gazawar na'urar.

- Sa'an nan, ta yin amfani da na'ura mai ba da hanya tsakanin hanyoyin sadarwa, da lokaci faifai ya lalace.

Matsalar-harbi

Yana da ma'ana don gyara firikwensin don rashin aiki kamar:

- shiga cikin firikwensin gurɓatawar PKV;

- kasancewar ruwa a cikin mahaɗin firikwensin;

- rushewar kushin kariya na igiyoyi ko na'urori masu auna firikwensin;

- canjin polarity na igiyoyin sigina;

- babu dangantaka da kayan doki;

- gajerun wayoyi na sigina zuwa ƙasa mai firikwensin;

- an rage ko ƙara ƙuri'a mai hawa na firikwensin da aiki tare faifai.

Table: aiki tare da ƙananan lahani

| Tsohuwar | Amsa |

|---|---|

| Shiga cikin firikwensin PKV da gurɓatawa |

|

| Kasancewar ruwa a cikin mahaɗin firikwensin |

|

| Garkuwa na firikwensin igiya ko kayan doki |

|

| Juya polarity na igiyoyin sigina |

|

| Ba a haɗa firikwensin zuwa kayan doki ba |

|

| Wayoyin siginar firikwensin sun gajarta zuwa ƙasa |

|

| Ragewa ko haɓaka izinin hawa na firikwensin da faifan aiki tare |

|

Yadda za a canza firikwensin matsayi na crankshaft?

Mahimman nuances waɗanda dole ne a kiyaye su yayin maye gurbin DPKV:

- Kafin rarrabuwa, dole ne a yi amfani da alamomin da ke nuna matsayi na ƙulli dangane da firikwensin, DPKV kanta, da alamar wayoyi da lambobin lantarki.

- Lokacin cirewa da shigar da sabon firikwensin PKV, ana ba da shawarar tabbatar da cewa faifan lokaci yana cikin yanayi mai kyau.

- Sauya mita tare da kayan aiki da firmware.

Don maye gurbin firikwensin PKV, kuna buƙatar:

- sabon na'urar aunawa;

- mai gwadawa ta atomatik;

- cavernometer;

- murza 10.

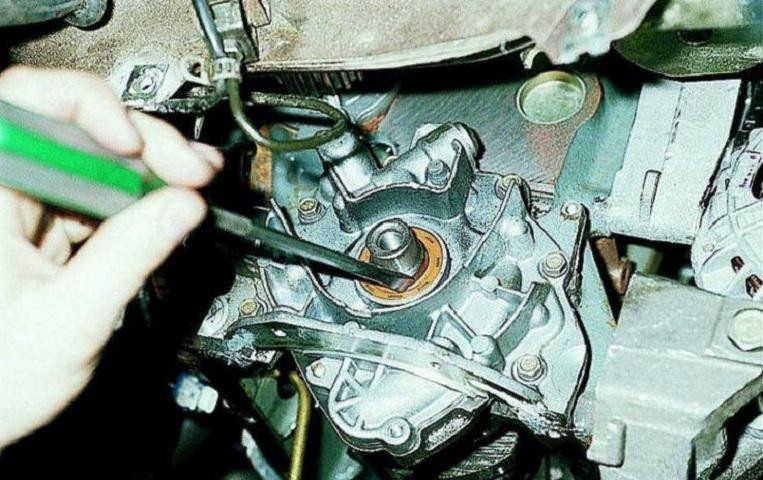

Algorithm na aiki

Don canza firikwensin matsayi na crankshaft da hannuwanku, kuna buƙatar:

- Kashe wutan.

- Kashe ƙarfin lantarki na na'urar ta hanyar cire haɗin tashar tashar daga mai sarrafawa.

- Tare da maƙarƙashiya, cire dunƙule mai gyara firikwensin, cire DPKV mara kyau.

- Yi amfani da tsumma don tsaftace wurin saukowa daga ma'ajiyar mai da datti.

- Shigar da sabon ma'aunin matsa lamba ta amfani da tsofaffin manne.

- Yi ma'auni na sarrafawa na tazarar da ke tsakanin haƙoran madaidaicin tuƙi da ma'aunin firikwensin ta amfani da ma'aunin vernier caliper. Dole ne sarari ya yi daidai da ƙimar masu zuwa: 1,0 + 0,41 mm. Idan ratar ya kasance ƙarami (mafi girma) fiye da ƙayyadaddun ƙimar yayin ma'aunin sarrafawa, dole ne a gyara matsayin firikwensin.

- Bincika juriya na firikwensin matsayi na crankshaft ta amfani da gwajin kai. Don firikwensin aiki, yakamata ya kasance cikin kewayon daga 550 zuwa 750 ohms.

- Sake saita kwamfutar tafiya don kashe siginar Duba Injin.

- Haɗa firikwensin matsayi na crankshaft zuwa mains (an shigar da mai haɗawa don wannan).

- Bincika aikin na'urar lantarki ta hanyoyi daban-daban: a hutawa da ƙarƙashin nauyi mai ƙarfi.