Allurar mai a cikin injinan mai. Abũbuwan amfãni, rashin amfani da yiwuwar matsaloli

Nau'in tsarin allura yana ƙayyade sigogin injin da farashin aiki. Yana shafar motsin kuzari, amfani da mai, fitar da hayaki da kuma kula da kuɗin mota.

Nau'in tsarin allura yana ƙayyade sigogin injin da farashin aiki. Yana shafar motsin kuzari, amfani da mai, fitar da hayaki da kuma kula da kuɗin mota.

Tarihin aikace-aikacen da ake amfani da shi na allurar mai a cikin injin konewa na ciki a cikin sufuri ya samo asali ne tun kafin yakin duniya na farko. Ko da a lokacin, jirgin sama na gaggawar neman sabbin hanyoyin magance injuna da za su iya inganta injunan injina da shawo kan matsalolin wutar lantarki a wurare daban-daban na jirgin. Allurar mai, wacce ta fara fitowa a cikin injin jirgin Faransa V8 na 1903, ta tabbatar da amfani. Sai a shekarar 1930 ne motar da aka yi wa allurar mai ta Mercedes 1951 SL ta yi muhawara, wadda ake dauka a matsayin na gaba a fagen. Duk da haka, a cikin nau'in wasanni, ita ce mota ta farko tare da allurar man fetur kai tsaye.

Tarihin aikace-aikacen da ake amfani da shi na allurar mai a cikin injin konewa na ciki a cikin sufuri ya samo asali ne tun kafin yakin duniya na farko. Ko da a lokacin, jirgin sama na gaggawar neman sabbin hanyoyin magance injuna da za su iya inganta injunan injina da shawo kan matsalolin wutar lantarki a wurare daban-daban na jirgin. Allurar mai, wacce ta fara fitowa a cikin injin jirgin Faransa V8 na 1903, ta tabbatar da amfani. Sai a shekarar 1930 ne motar da aka yi wa allurar mai ta Mercedes 1951 SL ta yi muhawara, wadda ake dauka a matsayin na gaba a fagen. Duk da haka, a cikin nau'in wasanni, ita ce mota ta farko tare da allurar man fetur kai tsaye.

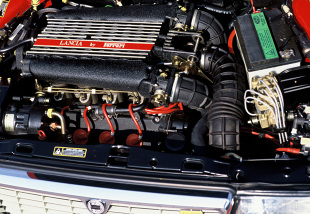

An fara amfani da allurar mai na lantarki a cikin 300 a cikin injin Chrysler na 1958. Allurar man fetur ta Multipoint ta fara bayyana akan motoci a shekarun 1981, amma galibi ana amfani da ita a cikin kayan alatu. An riga an fara amfani da famfunan lantarki masu ƙarfi don tabbatar da matsi mai kyau, amma har yanzu sarrafawa shine alhakin injiniyoyi, wanda kawai ya ɓace a cikin 600 tare da ƙarshen samar da Mercedes. Tsarin alluran har yanzu yana da tsada kuma bai canza zuwa motoci masu arha da shahararru ba. Amma lokacin da ya zama dole a cikin XNUMXs don shigar da masu canzawa a duk motoci, ba tare da la'akari da ajin su ba, dole ne a haɓaka nau'in allura mai rahusa.

Kasancewar mai haɓakawa yana buƙatar ƙarin madaidaicin iko na abun da ke cikin cakuda fiye da carburetors zasu iya bayarwa. Don haka aka ƙirƙiri allura mai maki ɗaya, ƙaramin sigar "maki mai yawa", amma isa ga buƙatun motoci masu arha. Tun daga karshen karni na 1996, ya fara bacewa daga kasuwa, wanda aka maye gurbinsa da injectors masu yawa, wanda a halin yanzu shine mafi mashahuri tsarin man fetur a cikin injuna. A cikin XNUMX, allurar mai kai tsaye ta yi daidaitattun halarta a karon akan Mitsubishi Carisma. Sabuwar fasahar tana buƙatar haɓaka sosai kuma da farko ta sami mabiya kaɗan.

Duk da haka, ta fuskar ƙaƙƙarfan ƙaƙƙarfan ƙa'idodin iskar gas, wanda tun daga farkonsa yana da tasiri mai ƙarfi ga ci gaban tsarin mai na motoci, masu zanen kaya daga ƙarshe sun matsa zuwa allurar mai kai tsaye. A cikin sabbin hanyoyin magancewa, ya zuwa yanzu kaɗan ne a adadi, sun haɗa nau'ikan allurar petur iri biyu - madaukai masu yawa da kai tsaye.

Duk da haka, ta fuskar ƙaƙƙarfan ƙaƙƙarfan ƙa'idodin iskar gas, wanda tun daga farkonsa yana da tasiri mai ƙarfi ga ci gaban tsarin mai na motoci, masu zanen kaya daga ƙarshe sun matsa zuwa allurar mai kai tsaye. A cikin sabbin hanyoyin magancewa, ya zuwa yanzu kaɗan ne a adadi, sun haɗa nau'ikan allurar petur iri biyu - madaukai masu yawa da kai tsaye.

Allurar Matuka Daya Kai tsaye

A cikin tsarin alluran maki guda, injin yana aiki da inje guda ɗaya. Ana shigar da shi a mashigar mashigar kayan abinci. Ana ba da man fetur a ƙarƙashin matsin kusan mashaya 1. The atomized man fetur gauraye da iska a gaban ci tashoshi na tashoshi da kai ga mutum cylinders.

Ana tsotse cakuda mai-iska a cikin tashoshi ba tare da takamaiman adadin cakuda ga kowane silinda ba. Saboda bambance-bambance a cikin tsayin tashoshi da ingancin ƙarewar su, wutar lantarki zuwa silinda ba ta dace ba. Amma akwai kuma amfani. Tun da hanyar cakuda man fetur da iska daga bututun ƙarfe zuwa ɗakin konewa yana da tsayi, man zai iya ƙafe da kyau lokacin da injin ya yi zafi sosai. A cikin yanayin sanyi, man fetur ba ya ƙafewa, bristles ya taru a kan bangon masu tarawa kuma ya shiga cikin ɗakin konewa a cikin nau'i na saukad da. A cikin wannan nau'i, ba zai iya ƙonewa gaba ɗaya a kan sake zagayowar aiki ba, wanda ke haifar da ƙarancin injunan injin a cikin lokacin dumi.

Sakamakon wannan shine ƙara yawan amfani da mai da yawan gubar iskar gas. Allurar maki ɗaya abu ne mai sauƙi kuma mai arha, baya buƙatar sassa da yawa, hadaddun nozzles da tsarin sarrafawa na ci gaba. Ƙananan farashin samarwa yana haifar da ƙananan farashin abin hawa, kuma gyare-gyare tare da allurar maki ɗaya yana da sauƙi. Irin wannan allurar ba a amfani da ita a cikin injinan motocin fasinja na zamani. Ana iya samuwa ne kawai a cikin samfura tare da ƙirar baya, kodayake an samar da shi a waje da Turai. Misali ɗaya shine Samand na Iran.

gata

– Zane mai sauƙi

- Ƙananan samarwa da farashin kulawa

– Ƙananan guba na iskar gas lokacin da injin yayi zafi

lahani

– Low man dosing daidaito

– Dangantakar yawan amfani da mai

- Babban yawan guba na iskar gas a cikin lokacin dumi na injin

– Rashin aikin yi dangane da injina

Allurar multipoint kai tsaye

Allurar multipoint kai tsaye

Tsawaita alluran kai tsaye mai maki ɗaya ita ce allurar kai tsaye mai ma'ana iri-iri tare da injector a kowace tashar jiragen ruwa. Ana isar da man ne bayan mantuwa, daf da bawul ɗin sha, masu allurar sun fi kusa da silinda, amma hanyar cakuɗewar iska/man har yanzu tana da tsayin da man zai yi tururi akan injin zafi. A gefe guda, lokacin dumama yana da ƙarancin ƙima don ƙaddamarwa a kan ganuwar tashar jiragen ruwa, tun da nisa tsakanin bututun ƙarfe da silinda ya fi guntu. A cikin tsarin maɓalli da yawa, ana ba da man fetur a matsa lamba na mashaya 2 zuwa 4.

Injector daban na kowane Silinda yana ba masu ƙira gabaɗaya sabbin dama ta fuskar haɓaka ƙarfin injin, rage yawan mai da rage fitar da hayaki. Da farko, ba a yi amfani da na'urorin sarrafawa na ci gaba ba, kuma duk nozzles suna mitar mai a lokaci guda. Wannan maganin bai yi kyau ba, tunda lokacin allurar bai faru a cikin kowane silinda ba a mafi fa'ida (lokacin da ya buga bawul ɗin da aka rufe). Ci gaban kayan lantarki ne kawai ya ba da damar gina ƙarin tsarin kula da ci gaba, godiya ga abin da allurar ta fara aiki daidai.

Da farko, an buɗe nozzles ɗin bi-biyu, sannan aka ɓullo da tsarin allurar mai na jeri, wanda kowane bututun ƙarfe ke buɗewa daban, a mafi kyawun lokacin da aka ba da silinda. Wannan bayani yana ba ku damar zaɓar daidai adadin man fetur don kowane bugun jini. Serial Multi-point System ya fi rikitarwa fiye da tsarin maki ɗaya, mafi tsada don ƙira kuma ya fi tsada don kiyayewa. Koyaya, yana ba ku damar haɓaka ingantaccen injin tare da ƙarancin amfani da mai da ƙarancin ƙarancin iskar gas.

gata

– High man dosing daidaito

– Karancin amfani da mai

– Da yawa dama dangane da injina kuzarin kawo cikas

– Low yawan guba na shaye gas

lahani

- Mahimmancin ƙirar ƙira

- Dangantakar yawan samarwa da farashin kulawa

Kai tsaye allura

Kai tsaye allura

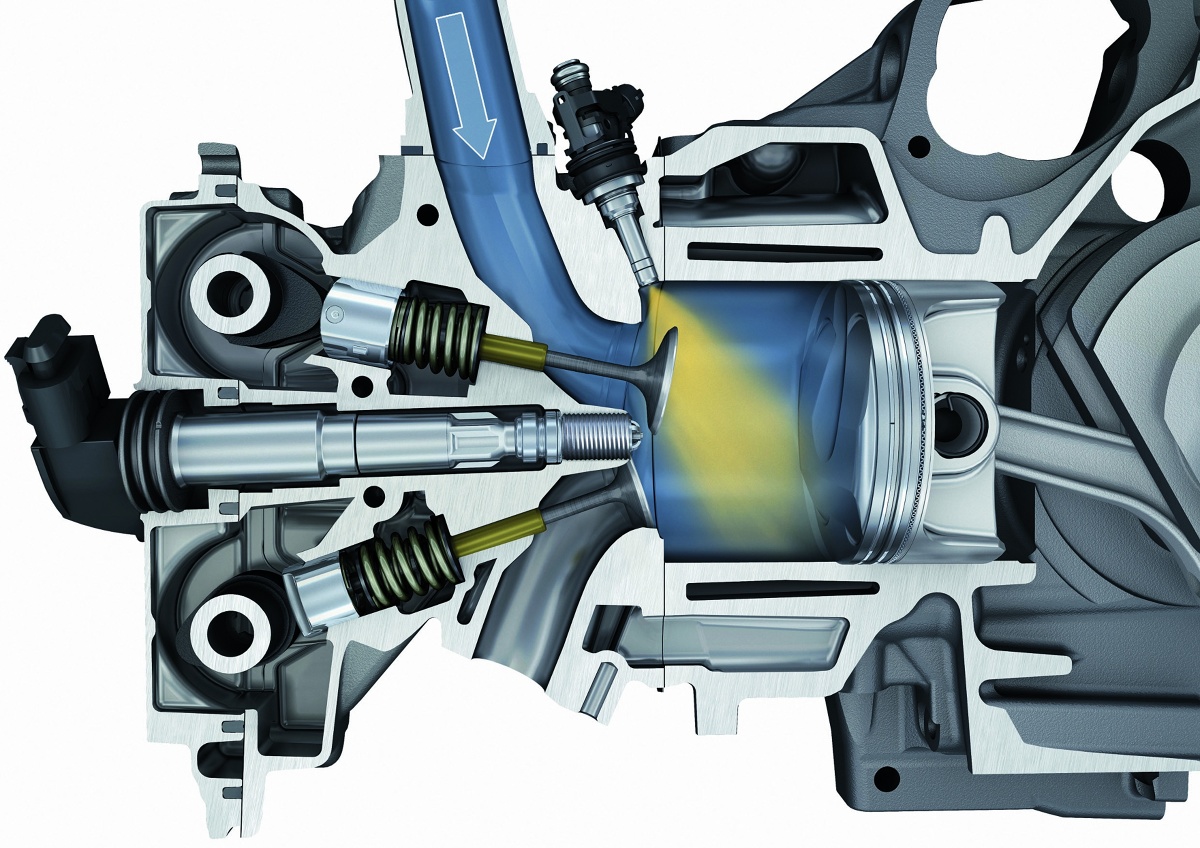

A cikin wannan bayani, an shigar da injector a cikin silinda kuma ya zuba man fetur kai tsaye a cikin ɗakin konewa. A gefe guda, wannan yana da fa'ida sosai, saboda yana ba ku damar sauya cajin man fetur da sauri sama da fistan. Bugu da kari, in mun gwada da sanyi man fetur kwantar da piston kambi da Silinda ganuwar da kyau, don haka yana yiwuwa a kara matsawa rabo da kuma samun mafi girma engine yadda ya dace ba tare da tsoron m konewa buga.

An ƙera injunan allura kai tsaye don ƙona gaurayawar iska/man mai da yawa a ƙananan nauyin injin don cimma ƙarancin ƙarancin mai. Duk da haka, ya juya cewa wannan yana haifar da matsaloli tare da wuce haddi na nitrogen oxides a cikin iskar gas, don kawar da abin da ya zama dole don shigar da tsarin tsaftacewa mai dacewa. Masu zanen kaya suna hulɗa da nitrogen oxides ta hanyoyi biyu: ta hanyar ƙara haɓakawa da rage girman girma, ko ta hanyar shigar da tsarin hadaddun tsarin nozzles biyu. Har ila yau, aikin ya nuna cewa tare da allurar mai kai tsaye, mummunan yanayin da ba a so ba na ajiyar carbon a cikin bututun sha na silinda da kuma a kan bawul ɗin shayarwa (raguwa a cikin ƙarfin injin, karuwa a yawan man fetur).

Wannan saboda duka tashar jiragen ruwa da bawul ɗin shayarwa ba a goge su tare da cakuda iska/mai kamar allurar kai tsaye. Saboda haka, ba a wanke su da kyaututtukan mai da ke shiga tsarin tsotsa daga tsarin iskar iska. Najasaccen mai yana taurare a ƙarƙashin rinjayar zafin jiki, yana haifar da ƙarar kauri na laka mara so.

gata

– Very high man dosing daidaito

– Yiwuwar kona gaurayawan ramammu

– Kyakkyawan ƙarfin injin injin tare da ƙarancin amfani da mai

lahani

- Tsari mai rikitarwa

– Very high samar da kuma kula farashin

– Matsaloli tare da wuce haddi nitrogen oxides a shaye gas

- Carbon adibas a cikin tsarin ci

Allura biyu - kai tsaye da kuma kaikaice

Allura biyu - kai tsaye da kuma kaikaice

Tsarin tsarin allura mai gauraya yana ɗaukar amfani da allurar kai tsaye da kai tsaye. Allurar kai tsaye tana aiki lokacin da injin yayi sanyi. Cakudar man fetur/iska yana gudana kai tsaye akan fistan kuma ba a keɓance naƙudawa. Lokacin da injin ya yi dumi kuma yana gudana ƙarƙashin nauyi mai sauƙi (tuki na yau da kullun, saurin hanzari), allura kai tsaye ta daina aiki kuma allurar kai tsaye mai maki da yawa ta ɗauki nauyin aikinsa. Fuel yana ƙafe mafi kyau, masu yin alluran kai tsaye masu tsada masu tsada ba sa aiki kuma ba sa ƙarewa, ana wanke bawul ɗin ci da cakuda mai da iska, don haka ajiya ba sa samuwa a kansu. A babban nauyin injin (karfin hanzari, tuki mai sauri), ana sake kunna allurar kai tsaye, wanda ke tabbatar da cikawar silinda cikin sauri.

gata

– Madaidaicin adadin man fetur

– Mafi kyawun isar da injin a kowane yanayi

– Kyakkyawan ƙarfin injin injin tare da ƙarancin amfani da mai

- Babu ajiyar carbon a cikin tsarin sha

lahani

- Babbar ƙira mai rikitarwa

- Matsakaicin yawan samarwa da farashin kulawa