Na'urar da ka'idar aiki na Multiport man injection MPI

Abubuwa

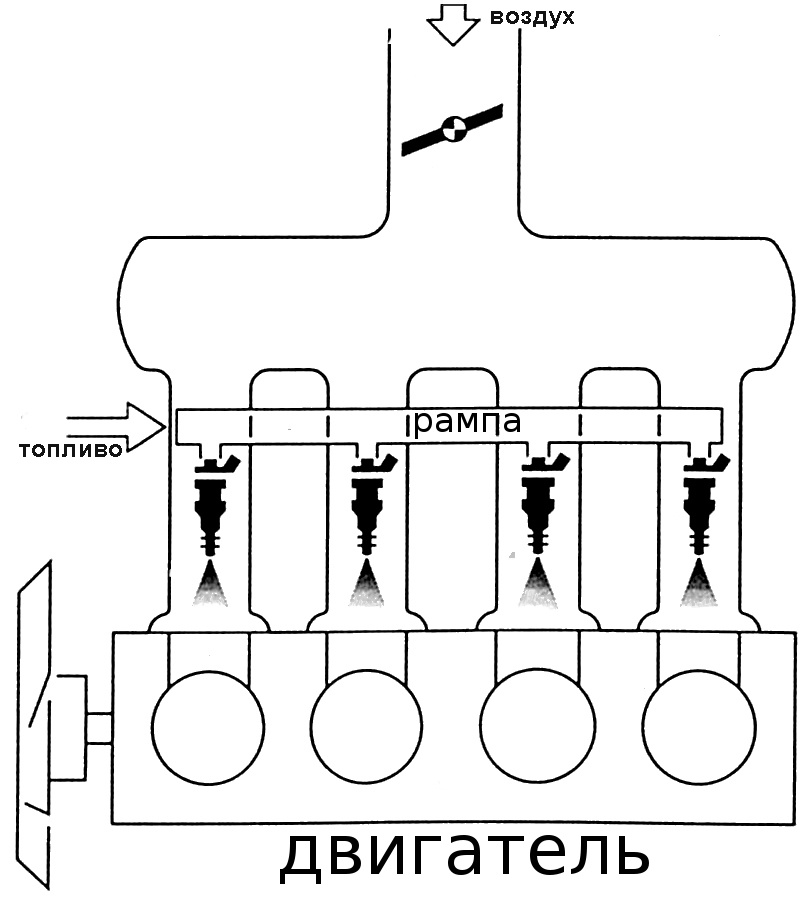

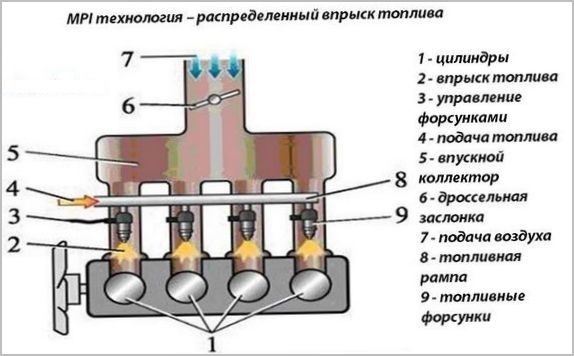

Tsarukan allurar man fetur da aka matsawa sun samo asali daga na'urori masu sauƙi zuwa na'urori masu rarrabawa ta hanyar lantarki waɗanda ke ɗaukar man fetur a cikin kowane silinda. Ana amfani da gajarta MPI (Injection Multi Point) don nuna ƙa'idar samar da fetur ta hanyar injectors na lantarki zuwa nau'in abin sha, gwargwadon yiwuwa zuwa wajen bawul ɗin sha. A halin yanzu, wannan ita ce hanyar da aka fi sani da kuma babbar hanyar tsara wutar lantarki na injinan mai.

Abin da ke kunshe a cikin tsarin

Babban makasudin wannan ginin shine daidaitaccen adadin adadin man fetur na cyclic, wato, ƙididdigewa da yanke adadin da ake buƙata na man fetur, dangane da yawan iska da aka ba da silinda da sauran mahimman sigogin injin na yanzu. Ana tabbatar da wannan ta kasancewar manyan abubuwan haɗin gwiwa:

- famfon mai yawanci yana cikin tankin gas;

- mai kula da matsa lamba da layin man fetur, na iya zama ɗaya ko biyu, tare da magudanar man fetur;

- ramp tare da injectors (injectors) sarrafawa ta hanyar motsa jiki;

- Naúrar sarrafa injin (ECU), a haƙiƙa, microcomputer ce tare da na'urori masu tasowa, dindindin, sake rubutawa da ƙwaƙwalwar samun damar bazuwar;

- na'urori masu auna firikwensin da yawa waɗanda ke lura da yanayin aikin injin, matsayi na sarrafawa da sauran tsarin abin hawa;

- actuators da bawuloli;

- Kayan aikin sarrafa kunna wuta da hadaddun software, an haɗa su gaba ɗaya cikin ECM.

- ƙarin hanyoyin rage yawan guba.

Ana rarraba kayan aikin a cikin cikin motar daga akwati zuwa sashin injin, ana haɗa nodes ta hanyar wayar lantarki, bas ɗin bayanan kwamfuta, man fetur, iska da layukan vacuum.

Aiki na ɗaiɗaikun raka'a da kayan aiki gabaɗaya

Ana samar da fetur daga tanki mai matsa lamba ta famfon lantarki da ke can. Motar lantarki da ɓangaren famfo suna aiki a cikin muhallin mai, ana sanyaya su kuma ana shafa su da shi. Ana tabbatar da lafiyar wuta ta rashin iskar iskar oxygen da ake buƙata don kunnawa; cakuɗe da iskar da aka wadatar da mai ba ta kunna wutar lantarki.

Bayan tacewa mataki biyu, man fetur ya shiga cikin layin mai. Matsin da ke cikinsa yana kiyaye karko tare da taimakon mai sarrafawa da aka gina a cikin famfo ko dogo. Ana mayar da wuce gona da iri a cikin tanki.

A daidai lokacin, electromagnets na injectors, daidaitawa tsakanin ramp da nau'in abin sha, suna karɓar siginar lantarki daga direbobin ECM don buɗewa. Ana shigar da man da aka matsa a zahiri a cikin bawul ɗin ci, a lokaci guda ana fesa kuma yana ƙafewa. Tun lokacin da aka tsaya tsayin daka na matsa lamba a kan injector, adadin man fetur da aka kawo ana ƙayyade lokacin buɗewa na bawul ɗin injector. Ana yin la'akari da canjin injin a cikin mai tarawa ta shirin mai sarrafawa.

Lokacin buɗe bututun ƙarfe ƙima ce da aka ƙididdige ta bisa bayanan da aka karɓa daga na'urori masu auna firikwensin:

- kwararar iska mai yawa ko cikakken matsi mai yawa;

- yawan zafin jiki na gas;

- digiri na bude maƙura;

- kasancewar alamun fashewar konewa;

- zafin injin;

- mita na juyawa da kuma matakai na matsayi na crankshaft da camshafts;

- kasancewar iskar oxygen a cikin iskar iskar gas kafin da kuma bayan mai canza catalytic.

Bugu da ƙari, ECM yana karɓar bayanai daga wasu tsarin abin hawa ta hanyar bas ɗin bayanai, yana ba da amsawar injin a yanayi daban-daban. Shirin toshe yana ci gaba da kula da ƙirar lissafi na jujjuyawar injin. Ana rubuta duk madaidaitan sa a cikin taswirori masu yawa.

Baya ga sarrafa allurar kai tsaye, tsarin yana ba da aikin wasu na'urori, coils da fitulun tartsatsi, iskar tanki, daidaitawar thermal da sauran ayyuka da yawa. ECM yana da kayan masarufi da software don aiwatar da binciken kansa da kuma baiwa direban bayanai game da faruwar kurakurai da rashin aiki.

A halin yanzu, alluran lokaci guda ɗaya kawai ga kowane silinda ake amfani da shi. A da, injectors yi aiki lokaci guda ko a cikin nau'i-nau'i, amma wannan bai inganta tafiyar matakai a cikin injin ba. Bayan gabatar da na'urori masu auna firikwensin matsayi na camshaft, kowane Silinda ya sami kulawa daban har ma da bincike.

Siffofin halaye, fa'idodi da rashin amfani

Kuna iya bambanta MPI daga sauran tsarin allura ta hanyar kasancewar nozzles guda ɗaya tare da ramp na gama-gari wanda aka nufa cikin da yawa. Allura mai lamba ɗaya tana da allura guda ɗaya wanda ya ɗauki wurin carburetor kuma yana kama da shi. Allura kai tsaye a cikin ɗakunan konewa yana da nozzles kama da kayan aikin man dizal tare da babban famfo da aka sanya a kan toshe. Ko da yake wani lokacin, don rama kurakuran alluran kai tsaye, ana ba da ita tare da madaidaicin ramp ɗin aiki don samar da wani ɓangaren mai ga ma'auni.

Bukatar tsara ingantaccen konewa a cikin silinda ya haifar da haɓaka kayan aikin MPI. Man fetur yana shiga cikin cakuda kamar yadda zai yiwu zuwa ɗakin konewa, yadda ya kamata ya fesa kuma ya kwashe. Wannan yana ba ku damar yin aiki a kan mafi yawan gaurayawan gauraya, tabbatar da inganci.

Daidaitaccen sarrafa kayan abinci na kwamfuta yana ba da damar saduwa da ƙa'idodin ƙaƙƙarfan guba. A lokaci guda, farashin kayan masarufi ba su da ɗanɗano, injuna masu MPI suna da arha don kera fiye da tsarin allura kai tsaye. Mafi girma da karko, da gyare-gyaren kuɗi kaɗan. Duk wannan yana bayyana fifikon MPI a cikin motocin zamani, musamman azuzuwan kasafin kuɗi.