Welding da gyaran robobi a cikin motoci

Abubuwa

- Hanyoyin gyaran filastik

- Zaɓuɓɓukan gyaran filastik

- Gyaran robobi ta hanyar walda

- Gyara tare da Uni-Weld da Fiberflex tef

- Gyaran ginshiƙai da suka karye

- Gyaran filastik tare da manne nan take

- Gyaran robobi tare da resin epoxy guda biyu

- Aikace-aikacen Putty

- Maganin farfajiya tare da fitila kafin a yi amfani da rigar rigar

- M aikace -aikace fenti

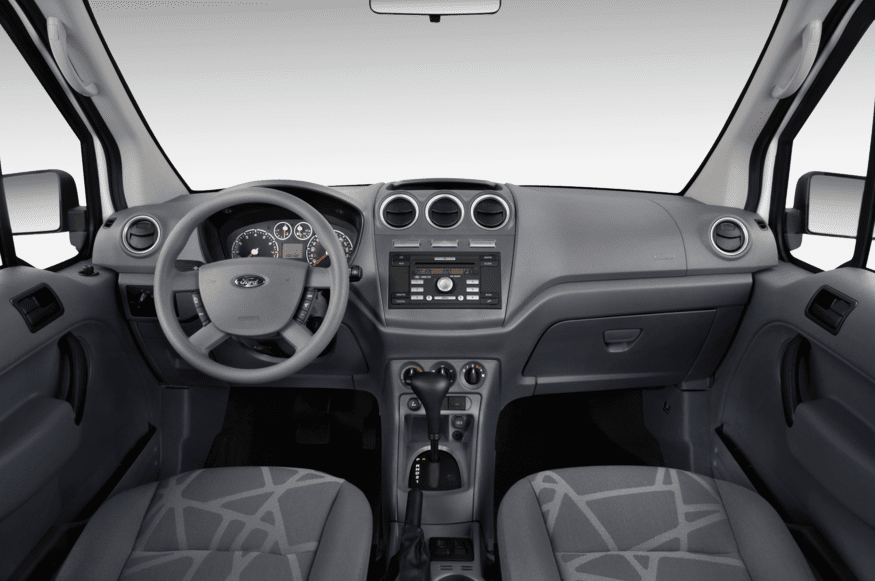

A yawancin motocin zamani, ana maye gurbin kayan ƙarfe da na robobi. Dalilin shi ne ƙananan nauyin motar, ƙananan amfani da man fetur, lalata kuma, ba shakka, ƙananan farashi. Lokacin gyaran sassan mota na filastik, wajibi ne a yi la'akari da bangaren tattalin arziki na gyaran ɗaya ko wani abu da kuma aikin filastik bayan gyarawa.

A yawancin motocin zamani, ana maye gurbin kayan ƙarfe da na robobi. Dalilin shi ne ƙananan nauyin motar, ƙananan amfani da man fetur, lalata kuma, ba shakka, ƙananan farashi. Lokacin gyaran sassan mota na filastik, wajibi ne a yi la'akari da bangaren tattalin arziki na gyaran ɗaya ko wani abu da kuma aikin filastik bayan gyarawa.

Hanyoyin gyaran filastik

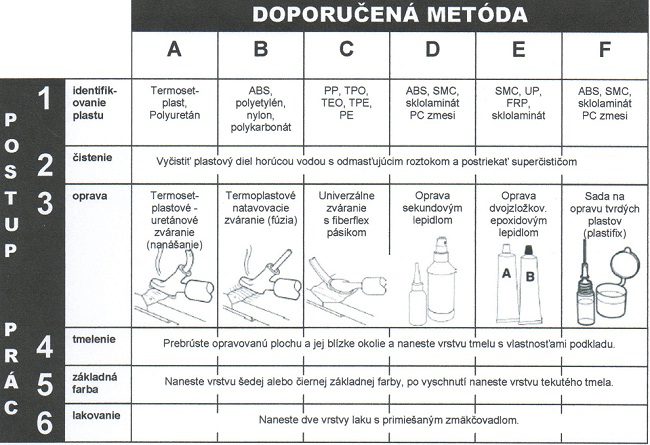

Tsarin aiki shine ganewar filastik, tsaftacewa, tsarin gyaran kanta, rufewa, fenti mai tushe, zanen.

Gano filastik

Hanya mafi sauƙi don gano robobi ita ce juya shi da duba ciki don neman alamar masana'anta. Sa'an nan nemo wannan alamar a cikin tebur da aka makala (Shafin Magana don Gyara Filastik) kuma, a cikin yanayin hanyoyin gyara da yawa da aka ba da shawarar, zaɓi wanda ya fi dacewa da ku. Idan ba zai yiwu a gano filastik ta alama ba, yana da matukar wuya a ƙayyade hanyar gyarawa, wannan yana buƙatar ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun kuma waɗanda za su iya zaɓar hanyar gyara da ta dace don ɓangaren.

Tebur Reference Reference Table

Tsabtace farfajiya kafin gyarawa

Don samun ƙarfin ƙarfin gyara da tsawon rayuwar sabis na ɓangaren da ake gyarawa, yana da mahimmanci a tsaftace farfajiyar sosai daga gurɓatattun abubuwa daban -daban, musamman a wurin da aka shirya gyara.

Mataki a'a. 1: Wanke ɓangarorin biyu tare da sabulu da ruwa kuma bushe tare da takarda ko fashewar iska.

Mataki a'a. 2: Fesa wurin da aka gyara tare da babban tsabtace (degreaser) kuma goge tare da bushewar zane. Koyaushe ninka tawul ɗin tare da sabon ɓangaren. Koyaushe gogewa a hanya ɗaya. Wannan hanya tana guje wa shigar datti a cikin ɓangaren da ake tsaftacewa.

Zaɓuɓɓukan gyaran filastik

Overhang gyara

Idan saman ya rufe, muna amfani da bindiga mai zafi don gyara wuraren da suka lalace. Lokacin dumama filastik, yana da mahimmanci a dumama shi gaba ɗaya. Kyakkyawan zafi yana nufin riƙe bindigar zafi a gefe ɗaya har sai kishiyar ta yi zafi sosai wanda ba za a iya riƙe farfaɗinta a hannunka ba. Bayan filastik ya yi zafi sosai, danna ɓangaren da ya lalace tare da guntun itace a madaidaicin matsayi kuma sanyaya da tsaftace wurin (zaku iya sanyaya shi da rafin iska ko rigar rigar).

Thermosetting robobi - polyurethanes (PUR, RIM) - robobi ne tare da ƙwaƙwalwar ajiya, godiya ga abin da suke dawowa kai tsaye zuwa matsayinsu na asali bayan dumama da bindiga mai zafi ko a cikin kwandon fenti.

Gyaran filastik thermosetting daga robobi uranium.

Urethane na mota ko PUR abu ne mai jure zafi. A wajen samar da shi, ana amfani da martani irin wanda aka yi amfani da shi wajen hada abin da ake hadawa da na'urar hardener - wato abubuwan ruwa guda 2 tare kuma an samar da wani abu mai karfi guda daya ba tare da yuwuwar komawa yadda yake ba. Saboda wannan dalili, filastik ba zai iya narke ba. Ba shi yiwuwa a narke filastik ta hanyar walda. Hanyar da ta fi dacewa don sanin idan bumper shine polyurethane shine a yi amfani da titin walda mai zafi zuwa bayan bumper. Idan urethane ne, robobin zai fara narkewa, kumfa, da hayaki (mai walda yana buƙatar yin zafi sosai don yin wannan). Bayan saman da aka ɗora ya yi sanyi, robobin ya kasance mai saurin taɓawa. Wannan alama ce da ke nuna cewa zafin jiki ya lalata tsarin kwayoyin halitta a cikin filastik. Ana iya gyara urethane na thermoset cikin sauƙi tare da walda mara iska, amma gyaran zai kasance da manne mai zafi fiye da walda (fusing sanda da goyan baya).

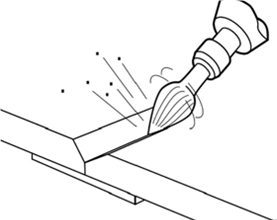

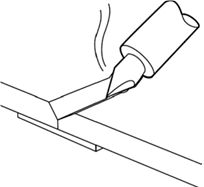

Shiri na V-grooves a yankin da ya lalace

Muna daidaitawa da manne sassan da suka lalace tare da tef ɗin aluminum. Don manyan yankuna, amintattu tare da matsawa. Hakanan zaka iya haɗa sassan tare da manne nan take (misali buga 2200). A bayan ɓangaren da za a gyara, muna yin injin V-groove a kan injin injin. Ba za mu iya amfani da ɗumi mai ɗumi ba maimakon injin niƙa don wannan tsari tunda kayan ba su da amfani. Sanya V-groove tare da sandpaper (z = 80) ko ma m. Ta hanyar yashi saman, muna samun ƙarin tsagi a cikin yanki mai niƙa. Hakanan a cikin yankin V-groove, cire varnish kuma ku tausasa gefen V-tsagi don sauyawa tsakanin farfajiya da V-tsagi ya yi laushi.

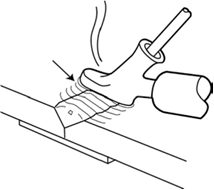

Jefa sanda a cikin V-tsagi

Dole ne a saita zafin jiki akan injin walda ta amfani da mai daidaitawa daidai da sanda mai haske (R1). Ta amfani da sandar polyurethane 5003R1, mun cimma gaskiyar cewa a fita daga takalmin walda, sanda yakamata ta fito cikin yanayin ruwa, mai haske ba tare da kumfa ba. Riƙe takalmin walda akan farfajiya don a haɗa shi kuma danna sandar da ta keɓe cikin V-tsagi tare da ita. Ba za mu yi zafi da babban kayan ba, amma mu zuba sandar walda a saman ta. Kada ku rikita tushe tare da damina. Kada mu manta cewa urethane baya narkewa. Kada a ƙara ƙarin sanduna fiye da 50 mm a lokaci guda. Muna fitar da sandar daga cikin takalmin kuma kafin narkakken sanda a cikin tsagi ya huce, santsi samansa da takalmi mai zafi.

Shiri na V-grooves a gefe guda

Bayan walda a gefen baya ya yi sanyi, maimaita yin V-tsagi, yashi da walda a gefe guda.

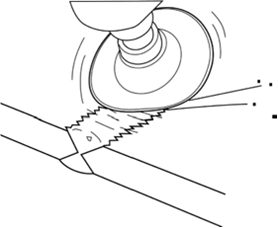

Nika walda zuwa farfajiya mai santsi

Yin amfani da m takarda, yashi walda zuwa wuri mai santsi. Ba za a iya haɗa haɗin urethane daidai ba, don haka za a buƙaci a yi amfani da rigar sealant a farfajiya don gyarawa. Kaɗan cire ƙarin abubuwa daga walda ta hanyar yashi don sealant ya rufe saman saman ko'ina.

Gyaran robobi ta hanyar walda

Ban da urethane, duk wani bumpers da mafi yawan robobin mota ana yin su ne daga thermoplastics. Wannan yana nufin cewa ana iya narke su lokacin zafi. Ana yin sassa na thermoplastic ta hanyar narkar da beads na filastik da kuma allurar kayan ruwa zuwa gyare-gyare inda suke kwantar da ƙarfi. Wannan yana nufin cewa thermoplastics ne fusible. Yawancin bumpers da aka samar an yi su ne da kayan TPO. TPO ya zama sanannen abu da sauri don samar da sassan ciki da injin injin. Ana iya waldawa TPO ta amfani da fasahar fusion ko sandar fiber na Fibreflex ta musamman wanda ke sa weld ɗin ya fi ɗorewa. Shahararrun kayan bumper na uku shine Xenoy, wanda shine mafi kyawun walda.

Shiri na V-grooves a yankin da ya lalace

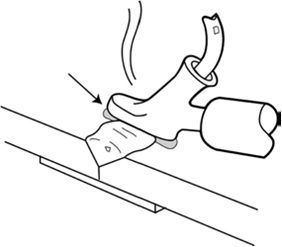

Muna daidaitawa da manne sassan da suka lalace tare da tef ɗin aluminum. Don manyan yankuna, amintar da su tare da matsawa. Hakanan zamu iya haɗa sassan tare da manne na iri na 2200. A bayan ɓangaren da aka gyara, muna yin injin V-groove akan injin injin. Don wannan tsari, zamu iya amfani da tip mai dumi maimakon injin injin, tunda kayan yana da ƙarfi. Cire fenti a kusa da gyaran da aka shirya ta sanding ɗin hannu kuma cire chamfer tsakanin farfajiya da V-tsagi.

Haɗa ainihin tare da kayan tushe

Mun saita zafin jiki a kan injin walda don dacewa da sandar walda da aka zaɓa, wanda muka ƙaddara yayin aikin tantancewa. A mafi yawan lokuta, sandar waldi tare da gammaye ya kamata ya fito da tsabta kuma ba fenti. Iyakar abin da kawai zai zama nailan, wanda ke juyawa translucent zuwa kodadde launin ruwan kasa. Sanya takalmin walda a kan tushe kuma sannu a hankali saka sandar a cikin V-tsagi. Sannu a hankali muna tura sandar a gaban mu don mu ga bayan mu wani tsagi mai siffar V cike da wannan kayan. Matsakaicin sandar walda 50 mm a cikin tsari ɗaya. Muna cire sandar daga cikin takalmin kuma, kafin sandar ta huce, a hankali a tura da haɗa kayan tare. Kyakkyawan kayan aiki shine gefen takalmin, wanda muke haɗe tsagi a cikin kayan tushe sannan mu haɗa su. Sanya farfajiya a hankali tare da zafi mai zafi. Bar tip mai zafi a duk lokacin haɗawa.

V-tsagi shiri da kishiyar gefen waldi

Bayan gefen baya ya yi sanyi gaba ɗaya, muna maimaita aikin shirya ramuka masu siffar V, niƙa da walda gefen gaba.

Wurin niƙa

Amfani da m takarda, yashi da walda zuwa m surface. Kaɗan cire ƙarin abubuwa daga walda ta hanyar yashi don sealant ya rufe saman saman ko'ina.

Gyara tare da Uni-Weld da Fiberflex tef

Sanda walda ta Duniya wani abu ne na musamman na gyara wanda za'a iya amfani dashi akan kowane filastik. Ba sandar walda ce ta gaske ba, ya fi wani nau'i na manne mai zafi. Lokacin da muka gyara wannan sandar, za mu yi amfani da zafin walda, maimakon maɗaurin sa. Sanda kamar Fiberflex tsiri yana da tsari mai ƙarfi sosai. Ana ƙarfafa shi da carbon da fiberglass don ƙarin ƙarfi. Fiberflex shine mafi kyawun bayani don TPO (kuma TEO, PP/EPDM) gyare-gyare watau. kayan da aka fi amfani da su don bumpers. Ana iya amfani da Fiberflex don gyara kowane nau'in robobi. Yana iya manne wa urethane da xenos. Idan ba mu da tabbacin abin da filastik muke waldawa, muna amfani da Fiberflex kawai. Wani fa'idar Fiberflex shine fusibility. Kyakkyawan tsarin walda yana rage girman amfani da abin rufewa.

Shiri na V-grooves a yankin da ya lalace

Muna daidaitawa da manne sassan da suka lalace tare da tef ɗin aluminium, gyara su tare da matsi matsawa akan manyan yankuna.Za ku iya haɗa sassan tare da manne irin na 2200. Faɗin ƙimar ƙirar V ya zama 25-30 mm. Yana da mahimmanci a yashi saman maimakon V-tsagi tare da sandpaper (girman grit kimanin. 60) don samun ƙarin yanki a cikin ƙananan ramukan. Idan muka yi amfani da sander vibration rotary don niƙa, za mu rage saurin zuwa mafi ƙanƙanta don hana narkewar kayan da thermoplastics ke da mahimmanci. Yin amfani da sandpaper (z = 80), cire varnish daga dukkan farfajiyar don gyarawa kuma yanke gefe tsakanin V-tsagi da farfajiya. Wannan yana ba mu damar watsawa mafi kyau kuma danna tef ɗin Fiberflex a wurin gyara.

Fiberflex tef narkewa

Sanya injin walda zuwa mafi girman zafin jiki kuma maye gurbin takalmin walda tare da matsi mai narkewa (ba tare da bututu mai jagora ba). Zai fi kyau a goge gefe ɗaya na tsiri na Fiberflex tare da farfajiya mai zafi don ɗan narke shi kuma a yi amfani da shi nan da nan zuwa substrate. Raba ɓangaren manne tare da gefen farantin zafi daga sauran murfin. Sannan narke tsiri a cikin V-tsagi. Ba ma ƙoƙarin haɗa kayan tushe tare da Fiberflex. Wannan hanyar tana kama da hanyar manne mai zafi.

Shiri na V-grooves da waldi na facade

Bayan Fiberflex na baya ya yi sanyi (mu ma za mu iya hanzarta aiwatar da ruwan sanyi), maimaita aikin tsagi, niƙa da walda. Hakanan zaka iya amfani da Fiberflex ɗan ƙaramin girma yayin da yake niƙa da kyau.

Nika

Da zarar Fiberflex weld ya huce, fara da yashi (z = 80) da saurin jinkiri. Kammala aikin yashi tare da sandpaper (z = 320). Duk rashin daidaituwa dole ne a cika shi da sealant.

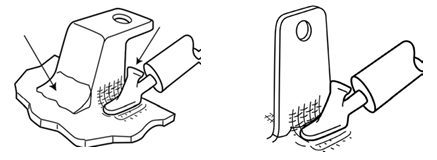

Gyaran ginshiƙai da suka karye

Yawancin bumpers na TEO suna da maƙallan da ke buƙatar sassauƙa don sauƙaƙe shigarwa. Ana iya gyara wannan tsarin da kyau tare da grid na bakin karfe da fiberflex. Na farko, roughen saman tare da rotary sander. Daga ragar bakin karfe, za mu yanke wani ɓangaren da ya dace don haɗa na'ura mai kwakwalwa da tushe a bangarorin biyu. Tare da tukwici mai zafi, danna waɗannan guda cikin filastik. Bayan narkewa da sanyaya, yashi saman saman da takarda don cire filaye masu haske. Etch sandar Fiberflex akan saman da aka yi magani. Tare da wannan gyare-gyare, raga yana ba da garantin ƙarfi da sassauci, kuma sandar fiber shine kawai suturar kwaskwarima.

Gyaran filastik tare da manne nan take

Tunda manne -haɗe na biyu suna haifar da shaidu masu ƙarfi, an fi son su don gyara robobi kamar ABS, PC, SMC, robobi masu wuya. Hakanan sun dace da ɓangarorin haɗe wuri ta hanyar gyara su kafin walda.

Fast gyara fasa

Babban fifikon haɗa sassan shine a ɗan fesa sassan da za a haɗa su da mai kunnawa. Muna girkawa da haɗa sassan. Yi amfani da tef ɗin aluminium 6481. Don manyan ɓangarori, yi amfani da ƙulle -ƙulle don tabbatar da cewa an riƙe ɓangarorin a lokacin haɗin gwiwa. Sauke ƙaramin manne nan take don cika tsagewar. Ana samun sakamako mafi kyau tare da mafi ƙarancin adadin man da aka yi wa haɗin gwiwa. Manne yana da bakin ciki don ya shiga cikin tsagewar. Fesa ƙarin adadin mai kunnawa don kammala tsari da ramuka masu girman gaske.

Cika tsagi da ramuka

Muna rufe rami a ƙasa tare da tef ɗin aluminum. Shirya V-notch a kewayen duk ramin ramin kuma yashi shi da wuraren da ke kewaye ta hanyar busa ƙurar. Fesa wurin da za a gyara shi da sauƙi tare da kunnawa. Cika rami tare da putty kuma yi amfani da 'yan saukad da manne. Mun daidaita kuma danna manne a cikin sealant tare da kayan aiki mai kaifi. Bayan sakan 5-10, yi amfani da haske mai kunnawa. Za a iya yin farfajiya nan take kuma a huda.

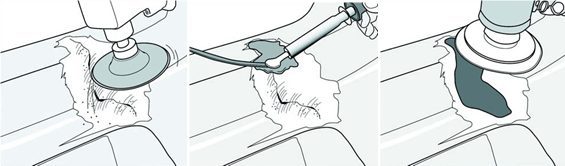

Gyaran robobi tare da resin epoxy guda biyu

Yashi bayan wurin da aka gyara tare da takarda yashi (z = 50 ko mafi girma). Zurfafa tsagi bayan niƙa shine kyakkyawan tushe don haɗin gwiwa mai ƙarfi. Sa'an nan kuma a sauƙaƙe yashi saman da takarda (z = 80), wanda kuma yana ba da gudummawa ga mafi kyawun haɗin gwiwa. Idan an yi amfani da kayan TEO, TPO ko PP, dole ne mu yi amfani da nau'in 1060FP mai goyan baya. Yada samfurin tare da goga a saman yashi kuma bari ya bushe. Muna sanya fiberglass tare da dukan tsawon ɓangaren da ya lalace. Idan wani sashe na SMC ya naɗe a kan tsagewa tare da wani ɓangaren da ya rage shi ma an yi shi da SMC, tabbatar da cewa wannan ɓangaren da ya wuce gona da iri ya wuce wurin lalacewa a kowace hanya da akalla 0,5mm. Za mu zaɓi manne mai sassa biyu masu dacewa wanda ya fi kama da ɓangaren da za a liƙa:

- Filler 2000 Flex (launin toka) mai sassauƙa

- 2010 Matsakaici mai sassauƙa mai sassauƙa mai sassauƙa (ja)

- 2020 SMC Hardset Filler (Grey) M

- 2021 Hard filler (rawaya) mai ƙarfi

Haɗa isasshen epoxy. Aiwatar da mayafi don rufe tef ɗin da fibers kuma a bar shi ya bushe na aƙalla mintina 15. A kan SMC, mun ƙirƙiri wani manne na manne don yanki na ƙarfafawa, wanda daga nan muka danna cikin gado da aka shirya. A wannan yanayin, bari manne ya bushe don aƙalla mintuna 20. Sanya fuskar ɓangaren da ya lalace tare da takarda (z = 50) da yashi V-tsagi a cikin fashewar. Daɗaɗa da zurfin wannan tsagi, ƙarfin haɗin yana da ƙarfi. Chamfer gefuna na tsagi na V, yashi saman tare da takarda (z = 80). Haɗa kuma yi amfani da murfin man madogarar epoxy da siffanta shi don ya zarce saman farfajiyar. Bari bushe don akalla minti 20. Daga nan ne za mu fara niƙa. Ta amfani da SMC, muna saka guntun ƙyallen filastik iri-iri a cikin V-tsagi da tsakanin keɓaɓɓun yadudduka na manne. Ta yin amfani da abin nadi mai juyawa, muna danna masana'anta a hankali a cikin manne kuma muna fitar da kumfa iska mara so. Muna sarrafa busasshiyar ƙasa tare da sandpaper (z = 80, sannan z = 180).

Aikace-aikacen Putty

Sanya farfajiyar da za a yi sanded da takarda mara nauyi. Shirya ƙaramin V-tsagi a wurin lalata. Dole ne a cire duk ɓangarorin masu sheki kafin amfani da abin rufe fuska, in ba haka ba adhesion mai kyau ba zai faru ba. Idan kayan polyolefin ne (PP, PE, TEO ko TPO-tushen filastik), muna amfani da manne mai goyan baya wanda yake da iska mai kyau. Mun zaɓi sealant epoxy wanda ya dace da sassaucin kayan tushe. Idan mai sassauci ne, yi amfani da 2000 Flex Filler 2 ko Semi-m Adhesive 2010. Idan da wahala, yi amfani da 2020 SMC Rigid Kit ko 2021 Rigid Filler. Haɗa adadin da aka ƙayyade na sealant epoxy. Za mu ƙirƙiri wani ɗan ƙaramin sealant Layer fiye da farfajiyar da ke kewaye. Ba za mu fara yin yashi a baya fiye da bayan mintuna 20 ba, don yin yashi muna amfani da takarda mai girman hatsi (z = 80, sannan 180).

Maganin farfajiya tare da fitila kafin a yi amfani da rigar rigar

Idan kayan rabin-olefin ne (TEO, TPO ko PP), yi amfani da manne mai goyan baya ga duk sassan fentin bisa ga hanyar da aka nuna akan alamar samfurin. A farfajiyar da za a gyara, yi amfani da fesa na asali na launin toka ko baƙar fata a cikin yadudduka na bakin ciki. Bayan bushewa, yashi saman tare da sandpaper (z = 320-400).

M aikace -aikace fenti

Bayan yashi tushe, busar da ƙura, yi amfani da samfur wanda ke santsi duk ɓarna a farfajiya don gyarawa. Haɗa samfurin tare da fenti wanda ba a tace shi ba. Sa'an nan kuma mu haɗa fenti tare da sirara, yi amfani da dukkan saman kwamitin gwargwadon umarnin masana'anta, ku guji fesa tabo. Don cimma daidaiton kallon ɓangaren filastik, muna amfani da fesa mai baƙar fata mai ɗumbin yawa.

Lokacin gyara filastik mota, dole ne mu yi la’akari, da farko, ɓangaren fasaha na yiwuwar gyara da kimanta gyaran da aka yi ta fuskar tattalin arziki. Wani lokaci yana da sauri, mafi dacewa kuma mai rahusa don siyan ɓangaren filastik da aka yi amfani da shi cikin kyakkyawan yanayi.