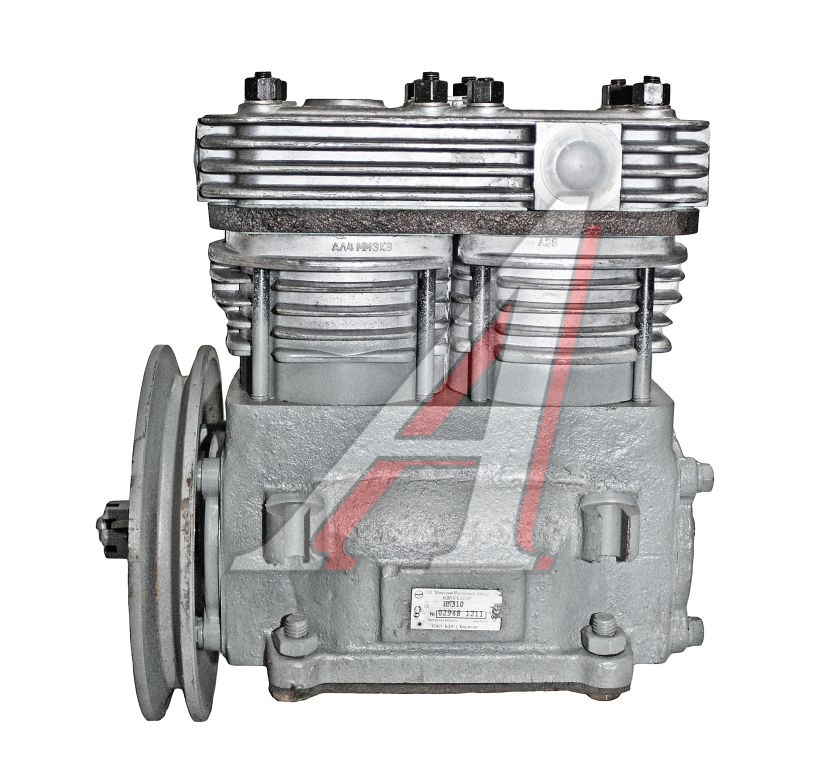

Compressor MAZ

Duba tashin hankali na kwampreso drive bel kullum. Ya kamata a shimfiɗa madauri don lokacin da kake danna tsakiyar gajeren reshe na madauri tare da karfi na 3 kg, karkatar da shi shine 5-8 mm. Idan bel ɗin yana jujjuya sama ko ƙasa da ƙimar ƙayyadaddun, daidaita tashin hankali, saboda ƙasa ko sama da haka na iya haifar da lalacewa da wuri.

Tsarin saitin shine kamar haka:

- sassauta ma'aunin ma'aunin goro da ƙwan ƙwanƙwasa;

- juya maƙarƙashiya mai tayar da hankali a kusa da agogo, daidaita ƙarfin bel;

- kara matse goro mai rike da axle mai danniya.

Jimlar yawan amfani da mai na kwampreso ya dogara da amincin hatimin tashar samar da mai a cikin murfin baya na kwampreso. Saboda haka, lokaci-lokaci bayan 10-000 kilomita na mota, cire murfin baya kuma duba amincin hatimin.

Idan ya cancanta, ana wanke sassan na'urar rufewa a cikin man dizal kuma an tsabtace su sosai da man coke.

Bayan 40-000 km na aiki, cire shugaban kwampreso, pistons mai tsabta, bawuloli, kujeru, maɓuɓɓugan ruwa da hanyoyin iska daga ajiyar carbon, cirewa da busa tudun tsotsa. A lokaci guda duba yanayin mai saukewa da kuma matsa lamba na bawuloli. Lappe sawa bawul waɗanda ba sa hatimi ga kujerun, kuma idan wannan ya kasa, maye gurbin su da sababbi. Sabbin bawuloli kuma dole ne a labe.

Lokacin duba mai saukewa, kula da motsi na plungers a cikin bushings, wanda dole ne ya koma matsayinsu na asali ba tare da ɗaure a ƙarƙashin aikin maɓuɓɓugan ruwa ba. Hakanan ana buƙatar bincika tsantsar haɗin kai tsakanin plunger da bushing. Dalilin rashin isasshen ƙarfi na iya zama zoben piston robar da aka sawa, wanda a cikin wannan yanayin dole ne a maye gurbinsa da sabon.

Lokacin dubawa da maye gurbin zobe, kar a cire shugaban kwampreso, amma cire bututun samar da iska, cire hannun rocker da bazara. Ana fitar da plunger daga cikin soket tare da ƙugiya na waya, wanda aka sanya shi a cikin rami mai diamita na 2,5 mm wanda yake a ƙarshen plunger, ko kuma a ba da iska zuwa tashar da ke kwance na na'urar allura.

Lubricate da plungers da CIATIM-201 GOST 6267-59 man shafawa kafin shigar da su a wuri.

Cikakken magudanar ruwa daga kai da shingen silinda na compressor ana aiwatar da shi ta hanyar bawul ɗin bawul ɗin da ke cikin gwiwa na bututun fitarwa. Idan ƙwanƙwasawa ya faru a cikin kwampreso saboda haɓakar rata tsakanin igiyoyi masu haɗawa da mujallu na crankshaft, maye gurbin kwamfutoci masu haɗa sandar bearings.

Karanta kuma Tukin mota ZIL-131

Idan compressor bai samar da matsa lamba da ake buƙata a cikin tsarin ba, da farko duba yanayin bututu da haɗin haɗin su, da maƙarƙashiya na bawuloli da mai sarrafa matsa lamba. Ana duba maƙarƙashiya ta kunne ko, idan ɗigon iskar ƙarami ne, tare da maganin sabulu. Abubuwan da za su iya haifar da zubar da iska na iya zama diaphragm leaks, wanda zai bayyana ta hanyar haɗin zaren a cikin babba na jiki ko ta rami a cikin ƙananan jiki na jiki idan bawul ɗin ba ta da ƙarfi. Sauya sassan da ke zubewa.

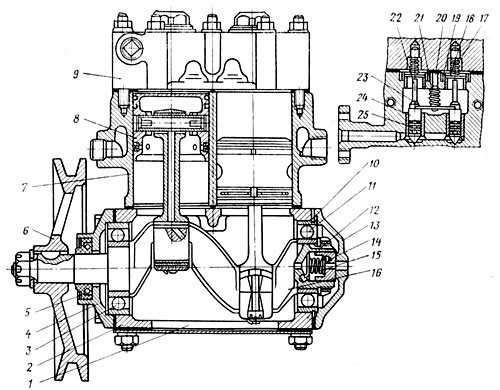

MAZ compressor na'urar

Compressor (Fig. 102) fistan ne mai silinda guda biyu wanda V-belt daga ɗigon fan. Kan silinda da crankcase suna makale a kan katangar silinda, kuma an makala akwati a jikin injin. A tsakiyar ɓangaren silinda toshe akwai wani rami a cikinsa inda na'urar saukar da kwampreso take.

Shinkafa 102.MAZ Compressor:

1 - filogi na jigilar kaya na kwampreso crankcase; 2 - kwampreso crankcase; 3 da 11 - bearings; 4 - murfin gaba na compressor; 5 - akwatin shaƙewa; 6 - ruwa; 7 - compressor cylinder block; 8 - fistan tare da sandar haɗi; 9 - shugaban block na cylinders na kwampreso; 10 - zobe mai riƙewa; 12 - tura goro; 13 - murfin baya na kwampreso crankcase; 14 - mai rufewa; 15 - hatimin bazara; 16 - crankshaft; 17 - ruwan sha bawul; 18 - bawul mai shiga; 19 - jagorar bawul ɗin sha; 20 - rocker hannu jagora spring; 21 - ruwan zafi; 22 - bawul mai shiga; 23 - dutse; 24 - ma'auni; 25 - zoben rufewa

An haɗu da tsarin lubrication na compressor. Ana ba da mai a ƙarƙashin matsin lamba daga layin mai na injin zuwa igiyoyin haɗin haɗin gwiwa. Ana fesa man da ke gudana daga igiyoyin haɗin kai, ya juya ya zama hazo mai kuma yana sa madubin Silinda mai.

The compressor coolant gudana ta cikin bututu daga injin sanyaya tsarin zuwa Silinda block, daga can zuwa Silinda shugaban da aka sallama a cikin tsotsa rami na ruwa famfo.

Karanta kuma Halayen fasaha na injin KamaZ

Iskar da ke shigar da kwampreta tana shiga ƙasa da bawulolin shigar da reed 18 dake cikin toshewar silinda. Ana sanya bawuloli masu shiga cikin jagorori 19, waɗanda ke iyakance ƙaura ta gefe. Daga sama, ana matse bawuloli a kan wurin zama ta wurin maɓuɓɓugar ruwan sha. Motsi na sama na bawul yana iyakance ta sandar jagorar bazara.

Yayin da fistan ke motsawa ƙasa, an ƙirƙiri wani wuri a cikin silinda da ke sama da shi. Tashar tana sadar da sarari sama da fistan tare da rami sama da bawul ɗin ci. Don haka, iskar da ke shiga compressor ta shawo kan ƙarfin bazara na bawul ɗin ci 17, ya ɗaga shi ya ruga cikin Silinda a bayan piston. Lokacin da piston ya motsa sama, iska yana matsawa, yana shawo kan ƙarfin sake saiti na bawul, ya kashe shi daga wurin zama kuma ya shiga cikin cavities da aka kafa daga kai ta hanyar nozzles a cikin tsarin pneumatic na mota.

Ana sauke kwampreso ta hanyar ketare iska ta buɗaɗɗen bawul ɗin shigarwa kamar haka.

Lokacin da matsakaicin matsa lamba na 7-7,5 kg / cm2 ya kai a cikin tsarin pneumatic, ana kunna mai sarrafa matsa lamba, wanda a lokaci guda ya wuce iska mai matsa lamba a cikin tashar kwance na mai saukewa.

A ƙarƙashin aikin ƙara matsa lamba, pistons 24 tare da sanduna 22 sun tashi, suna shawo kan matsa lamba na maɓuɓɓugan ruwa na bawul ɗin ci, da makaman roka 23 a lokaci guda suna yayyage bawul ɗin sha biyu daga wurin zama. Iska yana gudana daga wannan silinda zuwa wani cikin gibin da aka samu ta hanyoyin tashoshi, dangane da abin da aka dakatar da samar da iskar da aka matsa zuwa tsarin pneumatic na mota.

Bayan rage karfin iska a cikin tsarin, matsa lamba a cikin tashar kwance da aka yi magana da mai kula da matsa lamba yana raguwa, plungers da sanduna masu saukarwa suna ƙasa ƙarƙashin aikin maɓuɓɓugan ruwa, bawuloli masu shiga suna daidaitawa a kan kujerunsu, da aiwatar da tilasta iska cikin shiga. an sake maimaita tsarin pneumatic.

Mafi yawan lokuta, kwampreso yana sauke kaya, yana fitar da iska daga wannan Silinda zuwa wancan. Ana allurar iska a cikin tsarin pneumatic kawai lokacin da matsa lamba ya faɗi ƙasa da 6,5-6,8 kg/cm2. Wannan yana tabbatar da cewa matsa lamba a cikin tsarin pneumatic yana iyakance kuma yana rage lalacewa a kan sassan compressor.