Menene kuma ta yaya na'urori masu auna firikwensin don tsarin lubrication na injin ke aiki?

Abubuwa

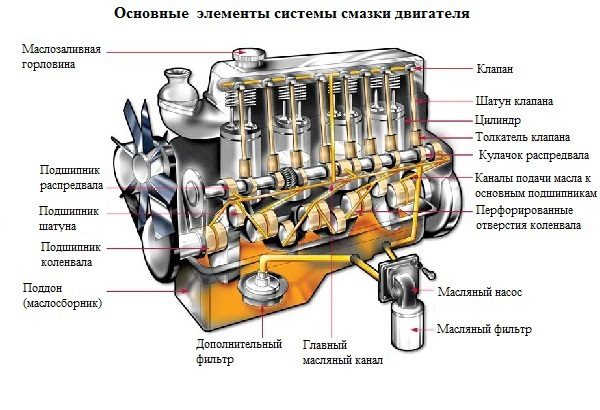

Don madaidaicin aiki na tsarin lubrication na injin, ana amfani da dukkan mahimman abubuwan firikwensin. Suna ba ku damar sarrafa matakin (ƙarar), matsin lamba, inganci (matakin gurɓatawa) da zafin mai na injin. Motocin zamani suna amfani da na’urorin firikwensin na inji da lantarki (lantarki). Babban aikin su shine yin rikodin duk wani karkacewa a cikin yanayin tsarin daga sigogi na yau da kullun da bayar da bayanan da suka dace ga alamun motar mota.

Manufar da na'urar firikwensin matsin mai

Na'urorin firikwensin mai suna cikin mahimman abubuwa a cikin tsarin. Suna daga cikin na farko da za su mayar da martani ga mafi ƙarancin matsala a cikin injin. Za'a iya samun firikwensin matsin lamba a wurare daban -daban: kusa da shugaban Silinda, kusa da bel ɗin lokaci, kusa da famfon mai, akan brackets zuwa tace, da sauransu.

Nau'ikan injina daban -daban na iya samun firikwensin matsa lamba daya ko biyu.

Na farko shine gaggawa (ƙaramin matsin lamba), wanda ke ƙayyade ko akwai matsin lamba a cikin tsarin, kuma idan ba ya nan, ana nuna shi ta hanyar kunna fitilar mai nuna rashin aiki a kan gaban mota.

Na biyu shine iko, ko cikakken matsa lamba.

Idan "jan mai zai iya" akan dashboard ɗin motar ya haskaka - an hana ƙarin motsi akan motar! Yin watsi da wannan buƙatun na iya haifar da manyan matsaloli a cikin tsarin gyaran injin.

Lura ga masu motoci. Fitilolin sarrafawa akan dashboard suna da launuka daban -daban saboda dalili. Duk wani alamun kurakurai ja yana hana ƙarin motsi na abin hawa. Alamar rawaya tana nuna cewa kuna buƙatar tuntuɓar sabis ɗin a nan gaba.

Ka'idar aiki na firikwensin gaggawa

Wannan nau'in firikwensin tilas ne ga duk abin hawa. Tsarin tsari, mai sauqi ne kuma ya ƙunshi abubuwa masu zuwa:

- gidaje;

- membrane;

- lambobin sadarwa;

- tafi.

An haɗa firikwensin gaggawa da fitilar mai nuna alama a cikin da'irar lantarki ta gama gari. Lokacin da injin yake kashewa kuma babu matsin lamba, diaphragm yana cikin madaidaiciyar matsayi, an rufe lambobin kewaye, kuma an janye mai turawa gaba ɗaya. A lokacin da aka fara injin, ana amfani da ƙarfin lantarki zuwa firikwensin lantarki, kuma fitilar da ke kan allo tana haskakawa na ɗan lokaci har sai an kafa matakin matsin mai a cikin tsarin.

Yana aiki akan membrane, wanda ke motsa turawa kuma yana buɗe lambobin kewaye. Lokacin da matsin lamba a cikin tsarin lubrication ya faɗi, diaphragm ya sake mikewa, kuma kewaye ya rufe, yana kunna hasken mai nuna alama.

Yadda cikakken firikwensin matsa lamba ke aiki

Na'urar analog ce wacce ke nuna matsin lamba na yanzu a cikin tsarin ta amfani da alamar nuna alama. Tsarin tsari, na’urar firikwensin inji don ɗaukar karatun matsin mai ya ƙunshi:

- gidaje;

- membranes (diaphragms);

- turawa;

- darjewa;

- nichrome winding.

Cikakkun masu watsa matsa lamba na iya zama rheostat ko tursasawa. A cikin akwati na farko, ɓangaren wutar lantarki a zahiri rheostat ne. Lokacin da injin ke aiki, matsi yana tasowa a cikin tsarin man shafawa, wanda ke aiki akan membrane kuma, a sakamakon haka, mai turawa yana canza matsayin slider ɗin da ke saman farantin tare da igiyar igiyar nichrome. Wannan yana haifar da canjin juriya da motsi na allurar alamar analog.

Na'urar firikwensin Pulse tana sanye da farantin thermobimetallic, kuma mai canza su ya ƙunshi lambobi biyu: na sama shine farantin tare da karkace da aka haɗa da kibiya mai nuna alama, da ƙaramin. Na ƙarshen yana hulɗa tare da diaphragm firikwensin kuma an gajarta shi ƙasa (ƙasa zuwa jikin abin hawa). A halin yanzu yana gudana ta manyan lambobin sadarwa na mai canzawa, yana dumama farantin sa na sama kuma yana haifar da canji a matsayin kibiya. Farantin bimetallic a cikin firikwensin shima nakasawa da buɗe lambobin har sai ya huce. Wannan yana tabbatar da cewa an rufe da'ira kuma an buɗe ta har abada. Matakan matsin lamba daban -daban a cikin tsarin lubrication suna da tabbataccen tasiri akan lambar ƙasa kuma canza lokacin buɗewa na kewaye (sanyaya farantin). A sakamakon haka, ana ba da ƙimar daban ta yanzu zuwa naúrar sarrafa lantarki, sannan ga mai nuna alama, wanda ke ƙayyade karatun matsin lamba na yanzu.

Na'urar firikwensin matakin mai, ko dipstick na lantarki

Kwanan nan, yawancin masu kera motoci suna yin watsi da amfani da madaidaicin dipstick don duba matakin mai na injin don fifita na'urorin firikwensin lantarki.

Na'urar firikwensin matakin mai (wani lokacin kuma ana kiranta dipstick na lantarki) yana lura da matakin ta atomatik yayin aikin abin hawa kuma yana aika karatun zuwa dashboard ga direba. Yawancin lokaci yana a kasan injin, a kan rami, ko kusa da matatun mai.

A tsari, an rarraba firikwensin matakin mai zuwa iri iri:

- Mechanical, ko taso kan ruwa. Ya ƙunshi jirgin ruwa wanda aka sanye shi da maganadisu na dindindin da bututu mai tsaye a tsaye tare da canjin reed. Lokacin da ƙimar mai ya canza, taso kan ruwa yana motsawa tare da bututu kuma lokacin da ƙaramin matakin ya kai, canjin reed yana rufe da'irar kuma yana ba da wutar lantarki zuwa fitilar mai nuna alama a kan allo.

- Zafi. A tsakiyar wannan na’ura waya ce mai zafin zafi, wanda ake amfani da ƙaramin ƙarfin wuta don ɗumama shi. Bayan isa zafin da aka saita, ana kashe wutar lantarki kuma ana sanyaya waya zuwa zafin mai. Dangane da lokacin da ya wuce, ƙimar mai a cikin tsarin an ƙaddara kuma an ba da siginar daidai.

- Electrothermal. Wannan nau'in firikwensin wani nau'in zafi ne. Tsarinsa kuma yana amfani da waya wanda ke canza juriya dangane da zafin dumama. Lokacin da aka nutsar da irin wannan waya a cikin injin injin, juriyarsa ta ragu, wanda ke ba da damar tantance ƙimar mai a cikin tsarin ta ƙimar ƙarfin fitarwa. Idan matakin mai yayi ƙasa, firikwensin yana aika siginar zuwa sashin sarrafawa, wanda ke kwatanta shi da bayanai akan zafin zafin mai da siginar mai nuna alama don kunnawa.

- Ultrasonic. Yana da tushen ultrasonic pulses directed cikin man kwanon rufi. Nunawa daga saman mai, ana dawo da irin waɗannan kumburin ga mai karɓa. Lokacin wucewar siginar daga lokacin aikawa zuwa dawowarsa yana ƙayyade adadin mai.

Yadda firikwensin zafin mai ke aiki

Na'urar firikwensin sarrafa zafin mai na injin wani ɓangaren zaɓi ne na tsarin shafawa. Babban aikinsa shine auna matakin dumamar mai da watsa bayanan da suka dace zuwa alamar dashboard. Ƙarshen na iya zama na lantarki (dijital) ko na inji (canji).

A yanayin zafi daban -daban, man yana canza kaddarorinsa na zahiri, wanda ke shafar aikin injiniya da karatun wasu na'urori masu auna firikwensin. Misali, man mai sanyi yana da karancin ruwa, wanda yakamata a yi la’akari da shi lokacin samun bayanan matakin mai. Idan man injin ya kai yanayin zafi sama da 130 ° C, zai fara ƙonewa, wanda zai iya haifar da raguwar ingancin sa sosai.

Tabbatar da inda injin firikwensin mai na injin yake ba shi da wahala - galibi ana sanya shi kai tsaye a cikin injin injin. A wasu samfuran mota, an haɗa shi da firikwensin matakin mai. Ayyukan firikwensin zafin jiki yana dogara ne akan amfani da kaddarorin thermistor na semiconductor.

Lokacin zafi, juriyarsa tana raguwa, wanda ke canza girman ƙarfin fitarwa, wanda aka kawo wa rukunin sarrafa lantarki. Yin nazarin bayanan da aka karɓa, ECU tana watsa bayanai zuwa dashboard gwargwadon saitunan da aka saita (coefficients).

Siffofin firikwensin ingancin mai

Na'urar firikwensin ingancin injin kuma zaɓi ne. Koyaya, tunda gurɓatattun abubuwa daban -daban (masu sanyaya ruwa, kayan sakawa, ajiyar carbon, da sauransu) babu makawa suna shiga cikin mai yayin aikin injin, ainihin rayuwar sabis yana raguwa, kuma ba koyaushe bane daidai don bin shawarwarin masana'anta don lokutan sauyawa.

Ka'idar aiki na firikwensin don sa ido kan ingancin injin injin ya dogara ne akan auna ma'aunin zafin wutar lantarki na matsakaici, wanda ke canzawa dangane da sinadaran. Wannan shine dalilin da ya sa aka sanya shi a cikin hanyar da za a nutsar da shi a cikin mai. Mafi sau da yawa, wannan yanki yana tsakanin matattara da bututun silinda.

Tsarin tsari, firikwensin don kula da ingancin mai shine polymer substrate wanda ake amfani da mayafin jan ƙarfe (electrodes). Ana jagorantar su biyu zuwa juna, suna yin firikwensin daban a cikin kowane biyun. Wannan yana ba ku damar samun mafi daidaitattun bayanai. Rabin rabin wayoyin suna nutse cikin mai, wanda ke da kaddarorin dielectric, yana sa faranti suyi aiki kamar capacitor. A kishiyar wutan lantarki, ana samar da wani ruwa wanda ke gudana zuwa amplifier. Na ƙarshen, dangane da girman na yanzu, yana ba da wani ƙarfin lantarki zuwa ECU na motar, inda aka kwatanta shi da ƙimar tunani. Dangane da sakamakon da aka samu, mai sarrafawa na iya fitar da saƙo game da ƙarancin mai zuwa dashboard.

Daidaitaccen aiki na firikwensin tsarin lubrication da sa ido kan yanayin mai yana tabbatar da ingantaccen aiki da haɓaka rayuwar sabis na injin, amma mafi mahimmanci - aminci da jin daɗin aikin abin hawa. Kamar sauran sassan, suna buƙatar dubawa na fasaha na yau da kullun, bincika sabis, da maye gurbin da ya dace lokacin da aka gano ɓarna.