Ciki kona injin silinda

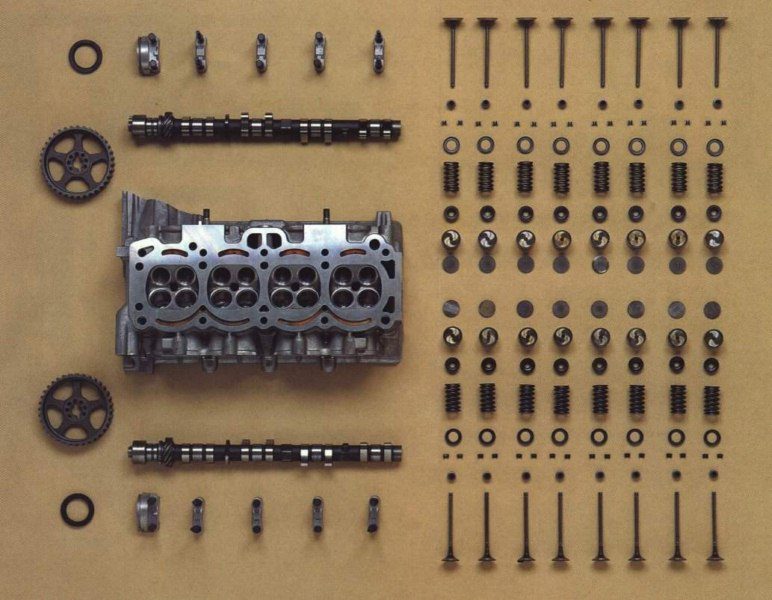

Abubuwa

- Ayyukan silinda

- Rabin kawunan silinda

- Silinda kai gasket

- Rufin silinda

- Babban halayen shugaban silinda na injin bugun jini biyu

- Babban halayen shugaban silinda na injin bugun jini huɗu

- Dakin konewa

- Shigarwa da fitarwa

- Jagoran bawul

- Bawuloli a cikin silinda shugaban injin

- Shugaban silinda biyu-bawul

- Shugaban silinda uku-bawul

- Shugaban silinda hudu

- Shugaban silinda guda biyar

Kalmar "kai silinda" ba ta zo kwatsam ba. Kamar yadda yake a cikin shugaban ɗan adam, ayyuka mafi rikitarwa da mahimmanci na injin konewa na ciki suna faruwa a cikin shugaban Silinda. Shugaban Silinda don haka wani ɓangare ne na injin konewa na ciki, wanda yake a ɓangarensa na sama (na sama). An haɗa shi tare da iskar iskar shaye-shaye da shaye-shaye, yana ƙunshe da sassa na injin bawul, injectors da walƙiya ko matosai masu haske. Shugaban Silinda ya rufe saman katangar silinda. Shugaban na iya zama ɗaya ga injin gabaɗayan, dabam ga kowane Silinda ko dabam don jere na daban na silinda (injin V-dimbin yawa). An ɗaure shi zuwa shingen Silinda tare da sukurori ko kusoshi.

Kalmar "kai silinda" ba ta zo kwatsam ba. Kamar yadda yake a cikin shugaban ɗan adam, ayyuka mafi rikitarwa da mahimmanci na injin konewa na ciki suna faruwa a cikin shugaban Silinda. Shugaban Silinda don haka wani ɓangare ne na injin konewa na ciki, wanda yake a ɓangarensa na sama (na sama). An haɗa shi tare da iskar iskar shaye-shaye da shaye-shaye, yana ƙunshe da sassa na injin bawul, injectors da walƙiya ko matosai masu haske. Shugaban Silinda ya rufe saman katangar silinda. Shugaban na iya zama ɗaya ga injin gabaɗayan, dabam ga kowane Silinda ko dabam don jere na daban na silinda (injin V-dimbin yawa). An ɗaure shi zuwa shingen Silinda tare da sukurori ko kusoshi.

Ayyukan silinda

- Yana samar da sararin konewa - yana samar da sarari matsawa ko sashinsa.

- Yana ba da musanya cajin silinda (injin bugun jini 4).

- Yana ba da sanyaya don ɗakin konewa, walƙiya da bawuloli.

- Yana rufe ɗakin konewa mai iskar gas da ruwa.

- Yana ba da wuri don sakawa walƙiya ko injector.

- Ɗauka da jagorantar matsa lamba na konewa - babban ƙarfin lantarki.

Rabin kawunan silinda

- Silinda yana jagorantar injunan bugun jini biyu da hudu.

- Silinda yana jagorantar walƙiya da injin ƙonewa.

- Shugabanni masu sanyaya iska ko ruwa.

- Rarraban kawuna don silinda ɗaya, kai don in-line ko injin V-dimbin yawa.

- Shugaban silinda da lokacin bawul.

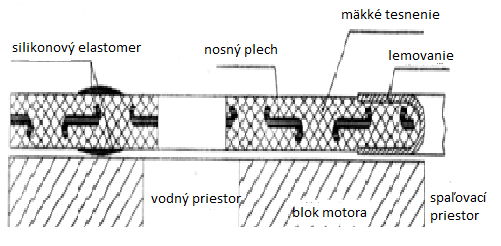

Silinda kai gasket

Akwai hatimi tsakanin shugaban silinda da toshe na silinda wanda ke rufe ɗakin konewa ta hanyar hermetically kuma yana hana mai da mai sanyaya tserewa (haɗawa). Muna raba hatimi a cikin abin da ake kira ƙarfe kuma a haɗe.

Ƙarfe, watau hatimin tagulla ko na aluminium, ana amfani da shi a cikin ƙananan injuna, masu saurin gudu, injunan sanyaya iska (babura, babura masu bugun jini har zuwa 250 cc). Injin da aka sanyaya ruwa yana amfani da hatimin da ke ƙunshe da sinadarin Organic mai ɗimbin yawa wanda aka haɗa akan tallafin ƙarfe na filastik.

Rufin silinda

Wani muhimmin sashin silinda shima murfi ne wanda ke rufe jirgin bawul ɗin kuma yana hana mai shiga cikin yanayin injin.

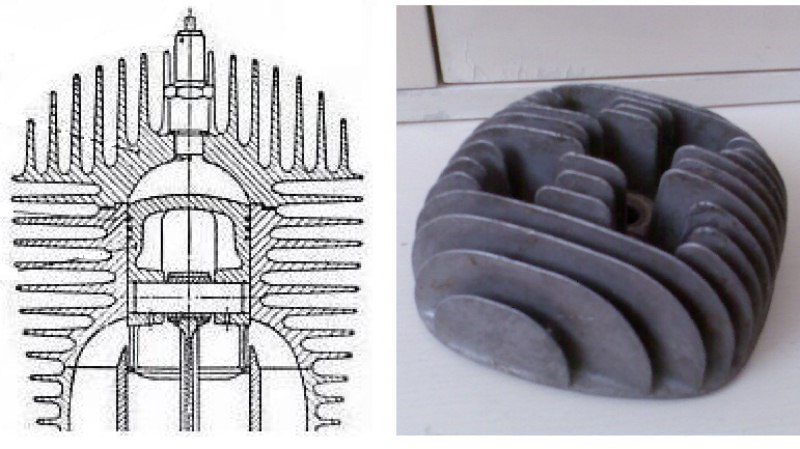

Babban halayen shugaban silinda na injin bugun jini biyu

Shugaban silinda don injin bugun jini sau biyu yawanci mai sauƙi ne, sanyaya iska (finned a saman) ko ruwa. Chamberakin ƙonewa na iya zama mai daidaitawa, biconvex ko madauwari, galibi tare da raunin anti-knock. Zaren walƙiyar walƙiya yana kan axis na silinda. Ana iya yin shi da baƙin ƙarfe simintin ƙarfe (tsohon ƙirar injiniya) ko gami na aluminium (wanda ake amfani da shi a halin yanzu). Haɗin kan injin injin bugun jini guda biyu zuwa toshe na silinda za a iya zare, flanged, haɗe tare da dunƙule dunƙule, ko ma daskararren kai.

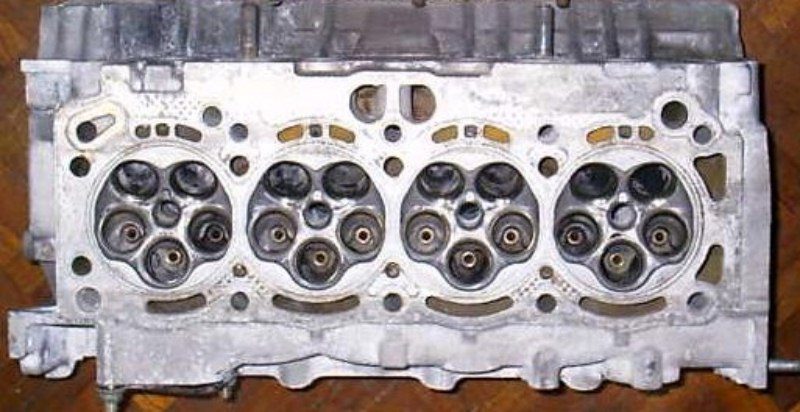

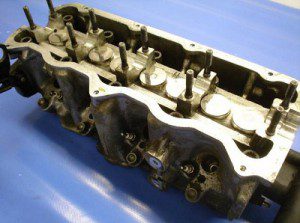

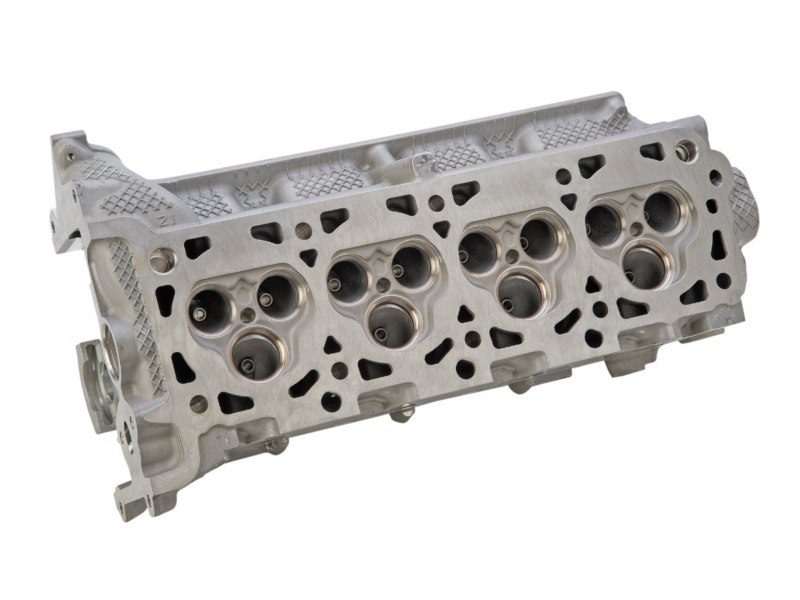

Babban halayen shugaban silinda na injin bugun jini huɗu

Zane-zanen kai don injunan bugun bugun jini kuma dole ne ya samar da canji a matsugunin injin silinda. Ya ƙunshi tashoshi masu shiga da fitarwa, sassan tsarin rarraba iskar gas wanda ke sarrafa bawuloli, bawul ɗin da kansu, tare da kujerunsu da jagororinsu, zaren don gyara walƙiya da nozzles, tashoshi don kwararar mai da sanyaya kafofin watsa labarai. Hakanan yana cikin ɗakin konewa. Saboda haka, ya fi rikitarwa a ƙira da siffa idan aka kwatanta da kan silinda na injin bugun bugun jini biyu. Shugaban Silinda na injin bugun bugun jini an yi shi ne daga ko dai simintin simintin gyare-gyaren launin toka, ko simintin simintin ƙarfe, ko ƙarfe na jabu - abin da ake kira simintin ƙarfe ko aluminum gami don injin sanyaya ruwa. Injin sanyaya iska suna amfani da allunan aluminum ko simintin ƙarfe. Ba a kusan taɓa yin amfani da ƙarfen simintin ƙarfe azaman kayan kai kuma an maye gurbin shi da gawa na aluminum. Mahimmin al'amari na samar da karafa masu haske ba shine ƙarancin nauyi ba kamar kyakkyawan yanayin zafi. Tun lokacin da tsarin konewa ke faruwa a cikin shugaban silinda, wanda ke haifar da zafi mai tsanani a cikin wannan ɓangaren injin, dole ne a canza zafi zuwa mai sanyaya da wuri-wuri. Sannan aluminium alloy abu ne mai dacewa sosai.

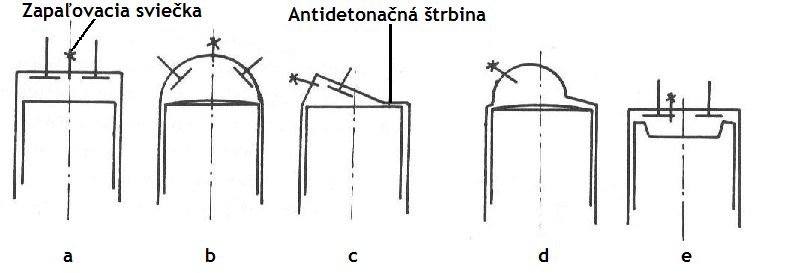

Dakin konewa

Chamberakin kone -kone shima wani muhimmin sashi ne na shugaban silinda. Dole ne ya zama madaidaicin siffa. Babban abubuwan da ake buƙata don ɗakin ƙonewa shine:

- Karamin da ke iyakance asarar zafi.

- Bada damar amfani da matsakaicin adadin bawuloli ko isasshen girman bawul.

- Mafi kyawun buɗewa na cika silinda.

- Sanya kyandir a wuri mafi wadata a ƙarshen matsi.

- Rigakafin ƙone wuta.

- Danne wuraren zafi.

Waɗannan buƙatun suna da mahimmanci saboda ɗakin konewa yana shafar samuwar hydrocarbons, yana ƙayyade hanyar ƙonawa, yana shafar amfani da mai, hayaniyar konewa da karfin juyi. Chamberakin ƙonawa kuma yana ƙaddara matsakaicin matsin lamba kuma yana shafar asarar zafi.

Siffofin ɗakin konewa

a - wanka, b - hemispherical, c - gaba, d - asymmetric hemispherical; e - Heronov-v pieste

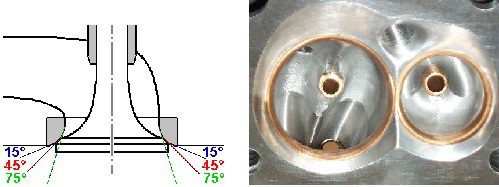

Shigarwa da fitarwa

Dukan tashoshin shiga da fitarwa suna ƙarewa tare da wurin zama bawul ko dai kai tsaye a cikin silinda ko tare da wurin zama da aka saka. An kafa madaidaicin bawul ɗin madaidaiciya a cikin kayan kai ko ana iya kiran shi. sirdi a cikin layi wanda aka yi da kayan gami mai inganci. Fuskokin tuntuɓa daidai ƙasa zuwa girman. Kuskuren bevel na wurin zama bawul ɗin shine mafi yawan 45 °, tunda wannan ƙimar tana samun kyakkyawan ƙarfi lokacin da aka rufe bawul ɗin kuma wurin yana tsabtace kansa. Wasu lokuta ana karkatar da bawul ɗin tsotsa a 30 ° don mafi kyawun kwarara a cikin wurin zama.

Jagoran bawul

Bawul ɗin yana motsawa cikin jagororin bawul. Za'a iya yin jagorar bawul ɗin daga ƙarfe na ƙarfe, gami da allurar tagulla, ko sanya kai tsaye a cikin kayan silinda.

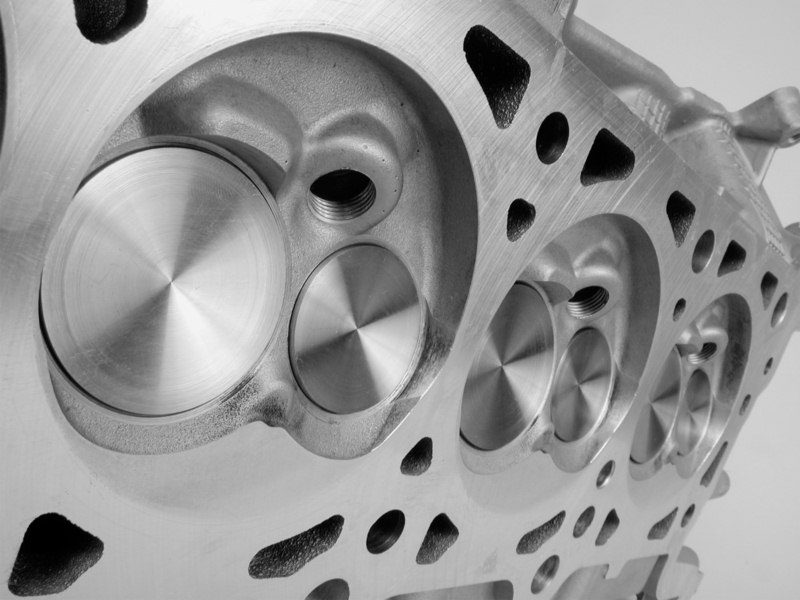

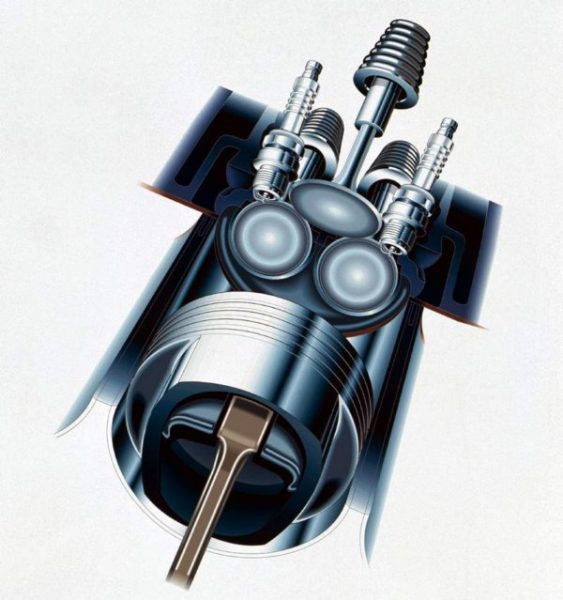

Bawuloli a cikin silinda shugaban injin

Suna motsawa cikin jagora, kuma bawuloli kansu suna kan kujerun. Bawul ɗin a matsayin wani ɓangare na bawul ɗin sarrafawa don rama injunan konewa na ciki yana fuskantar matsin lamba na injiniya da zafi yayin aiki. Daga mahangar injiniya, galibi an ɗora shi da matsin lamba na iskar gas a cikin ɗakin konewa, da kuma ikon sarrafawa da aka umarta daga cam (jack), ƙarfin rashin ƙarfi yayin motsi mai jujjuyawa, kazalika da gogayya ta inji. kaina. Damuwar zafi tana da mahimmanci iri ɗaya, tunda bawul ɗin galibi yana shafar yanayin zafin da ke cikin ɗakin ƙonawa da kuma yanayin zafin da ke kewaye da iskar gas mai zafi (bawuloli masu fitar da ruwa). Shine bawul ɗin fitarwa, musamman a cikin manyan injunan da aka ɗora, waɗanda aka fallasa su da matsanancin nauyin zafi, kuma zazzabin na gida na iya kaiwa 900 ° C. Za a iya canza zafi zuwa wurin zama tare da rufe bawul ɗin da kuma bawul ɗin. Canja wurin zafi daga kai zuwa tushe zai iya ƙaruwa ta hanyar cike ramin da ke cikin bawul ɗin tare da kayan da suka dace. Mafi yawan lokuta, ana amfani da iskar gas mai ɗorewa, wanda ke cika ramin rami rabin, don haka lokacin da bawul ɗin ke motsawa, cikin ya cika da ruwa sosai. Ramin ramin a cikin ƙananan injuna (fasinja) ana yin shi ta hanyar haƙa rami; a cikin yanayin manyan injuna, ɓangaren ɓangaren bawul ɗin na iya zama rami. Jigon bawul ɗin galibi ana sanya shi chrome. Don haka, nauyin zafi ba iri ɗaya ba ne don bawuloli daban -daban, shi ma ya dogara da tsarin konewa da kansa kuma yana haifar da matsalolin zafi a cikin bawul ɗin.

Kawunan bawul ɗin shigarwa yawanci suna girma a diamita fiye da bawul ɗin shayewa. Tare da adadi mara kyau na bawuloli (3, 5), akwai ƙarin bawuloli masu sha akan silinda fiye da bawul ɗin shayewa. Wannan shi ne saboda abin da ake bukata don cimma matsakaicin yiwuwar - mafi kyawun iko na musamman kuma, sabili da haka, mafi kyawun yuwuwar cika silinda tare da cakuda mai wuta da iska.

Don samar da bawuloli masu shayarwa, galibi ana amfani da ƙarfe tare da tsarin pearlite, an haɗa shi da silicon, nickel, tungsten, da sauransu. Ana fitar da bawul ɗin da aka fallasa ga danniya mai zafi daga ƙira mai ƙarfi (chromium-nickel) tare da tsarin austenitic. Karfe kayan aiki na ƙarfe ko wani abu na musamman an haɗa shi zuwa wurin zama. tauraron dan adam (gami mai narkewa na cobalt tare da chromium, carbon, tungsten ko wasu abubuwa).

Shugaban silinda biyu-bawul

Shugaban silinda uku-bawul

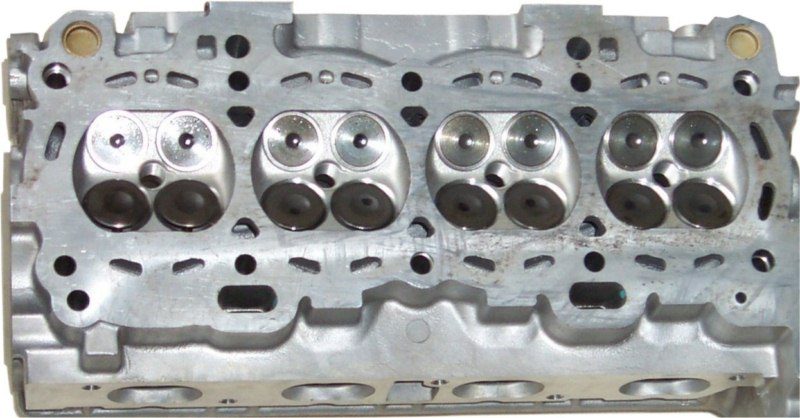

Shugaban silinda hudu

Shugaban silinda guda biyar