Na'ura mai ƙarfi MAZ

Daidaitawar izinin haɗin gwiwa na ƙwallon ƙafa na mai haɓakawa na hydraulic MAZ.

Bayyanar giɓi a cikin fil ɗin ƙwallon yana tasiri sosai ga wasan gabaɗayan naúrar kai. Sau da yawa, rata a cikin fil ɗin ƙwallon 9 yana ƙaruwa (duba siffa 94), wanda aka haɗa sandar madaidaiciya, tun da yawancin ƙarfin da ake yadawa ta wannan fil ɗin ƙwallon fiye da ta hanyar fil ɗin ƙwallon tuƙi.

Don daidaita ramukan fitilun ƙwallon ƙwallon, an tarwatsa ɓangarorin na'ura mai haɓakawa na hydraulic. Sabili da haka, yana da kyau a aiwatar da gyare-gyare a kan haɓakar hydraulic da aka cire daga motar.

Tsarin saitin shine kamar haka.

Jawo daidaita tazarar haɗin gwiwa:

- cire bututu;

- manne mai kara kuzari a cikin vise kuma sassauta goro na kulle akan silinda;

- Cire jikin hinge daga silinda;

- gyara jikkunan hinge a cikin mataimakin, sassauta dunƙule makullin akan goro 7 (duba siffa 94);

- a danne goro 7 har sai ya tsaya, sannan a danne makullin makulli sosai;

- Haɗa jikin kwallaye tare da silinda. Ƙarfafa har zuwa lokacin da zai tafi kuma cire shi zuwa wani wuri wanda zai ba da damar haɗa bututun.

Daidaita wasan haɗin gwiwa pivot:

- gyara hydraulic booster a cikin wani mataimakin;

- cire murfin 12 daga mai rarrabawa, cirewa kuma cire goro;

- Cire sukurori da ke riƙe da mahalli kuma cire gidan tare da nada;

- kwance kulle kulle 29;

- dunƙule hular 29 gabaɗaya kuma a mayar da ita har sai rami na dunƙule makullin ya daidaita da ramin mafi kusa a cikin kofin 36;

- ƙara kulle kulle har sai ya tsaya;

- shigar da kiyaye jikin nada;

- a saka spool a cikin hannun rigar jiki, a saka hula 32, sai a matsa goro har sai ya tsaya, sai a kwance shi da 1/12 sannan a yanke zaren;

- shigar da amintaccen murfin 12 da bututu;

- shigar da na'ura mai aiki da karfin ruwa a kan mota.

Matsalolin sarrafawa mai yiwuwa da hanyoyin kawar da su ana ba su akan shafi na goma sha ɗaya.

| Dalilin rashin aiki | hanya |

| Rashin isa ko rashin daidaituwa | |

| Rashin isasshen tashin hankali na famfo drive bel | Daidaita tashin hankali bel |

| Ƙananan matakin mai a cikin tafki mai sarrafa wutar lantarki | Ƙara mai |

| Kumfa mai a cikin tanki, kasancewar iska a cikin tsarin hydraulic | Cire iska daga tsarin. Idan iska ba ta zub da jini ba, duba duk hanyoyin haɗin gwiwa don ɗigogi. |

| Cikakken rashin riba a saurin injin iri-iri | |

| Toshewar bututun fitarwa da magudanar ruwa na tsarin ruwa | Wargaza layin kuma duba patency na bututu da hoses da ke cikin su |

| Babu motsi lokacin juyawa zuwa gefe guda | |

| Kame spool mai rarraba wutar lantarki | Kashe mai rarrabawa, nemo kuma kawar da dalilin cunkoso |

| Jamming na mai siffar siffar yatsa na na'ura mai aiki da karfin ruwa servomotor | Kwakkwance na'ura mai kara kuzari da kawar da dalilin cinkoson kofin |

| Komawa a cikin haɗin spool tare da gilashin fil ɗin ƙwallon ƙafa na tuƙi | Cire murfin gaba na mai rarrabawa, kawar da wasan ta hanyar matsawa goro har sai an zaɓi tazarar da ke tsakanin goro da spool, sa'an nan kuma fil ɗin cotter. |

MAZ na'ura mai aiki da karfin ruwa gyara

Cire na'urar kara kuzari daga motar. Don cire shi kuna buƙatar:

- cire haɗin matsa lamba da magudanar ruwa daga mai haɓaka hydraulic;

- Cire goro na abin da aka haɗa haɗin gwiwa da ke riƙe da fil a kan sandar servomotor na na'ura mai aiki da karfin ruwa, sa'an nan kuma ka buga gunkin daga sashin;

- buga ingarma na shugaban sandar haɓakar hydraulic;

- Cire da kuma cire ƙwayayen da ke tabbatar da abin ƙarfafa na'ura mai ƙarfi zuwa ga tuƙi da kuma hannun da ke biyo baya;

- ta yin amfani da naushi, danna yatsanka daga cikin ramukan da ke hannun tutiya da hanyar haɗin kai. Cire kayan haɓakar hydraulic. Hanyar da za a yi amfani da kayan haɓaka na hydraulic shine kamar haka: cire bututu da kayan aiki;

- sassauta haɗin da aka zare na kan karami tare da kara kuma ku kwance kan. Cire mai wanki mai gyara waje; murfi;

- lokacin da ake sawa robar, sai a tarwatsa kan, wanda don haka sai a kwance goro a daka dashen karfe, sannan a datse robar;

- cire kullun da ke riƙe da murfin, murfin da mai wanka na ciki daga dutsen;

- kwance screws da ke riƙe da murfin silinda na wutar lantarki, cire mai wanki, cire zobe mai riƙewa ta hanyar zamewa murfin Silinda baya, cire murfin;

- cire piston tare da sanda kuma tarwatsa shi;

- Cire nut ɗin kulle na Silinda kuma juya Silinda;

- cire clamps don ɗaure gland na ƙwallon ƙwallon ƙafa da glandan kansu;

- Cire dunƙule makullin, cire kwaya mai daidaitawa 7 (duba hoto 94), cire mai turawa 8, bazara, busassun da ƙwallon ƙwallon 9;

- Cire murfin maɗauran sukurori 12 kuma cire murfin; Cire goro mai ɗaure coil ɗin kuma cire shi, cire hular 32;

- kwance screws ɗin da ke riƙe jikin nada, fitar da jikin, fitar da nada;

- Cire dunƙule makullin, cire filogi 29, cire guntun, mai turawa 8, bazara, crackers da fil 10;

- cire gilashin 36;

- Cire cak ɗin bawul ɗin cak 35 sannan ka cire ruwan ball i.

Bayan tarwatsewa, a hankali a duba sassan ma'aunin haɓakar hydraulic.

Ba a yarda da ƙulle-ƙulle da laƙabi a saman spool ɗin, gilashin fil ɗin ledar ƙwallon ƙafa da jikinsu. Wuraren da ke gudana na ƙwanƙwasa ƙwallo da rocker dole ne su kasance masu kuɓuta daga ɓarna da lalacewa da yawa, kuma zoben roba dole ne su nuna lalacewa da lalacewa.

Idan an sami lalacewa, maye gurbin waɗannan sassa da sababbi.

Shigar da ƙaramar ruwa a cikin juzu'i na cirewa. Kafin haɗuwa, wuraren shafa na nada, gilashi da yatsunsu; man shafawa da wani bakin ciki mai mai kuma a tabbata cewa coil da kofin suna tafiya cikin yardar kaina a cikin gidajensu, ba tare da tsangwama ba.

Daidaita izinin haɗin gwiwar ƙwallon kamar yadda aka bayyana a sama.

Bayan hadawa, sai a shafa wa ƙwal ɗin da man shafawa ta hanyar mai 18.

Shigar da injin ƙararrawa a kan motar a cikin tsarin cirewa.

Lokacin shigar da ƙarar na'ura mai aiki da karfin ruwa, matsar da kwayoyi masu kiyaye fil ɗin sosai kuma a murƙushe su a hankali.

Kula da kayan haɓaka mai ƙarfi MAZ

A lokacin aikin motar, bincika tsari na ɗaure na'ura mai ba da hanya tsakanin hanyoyin sadarwa zuwa gaɓar firam ɗin motar, daɗaɗɗen famfo mai haɓaka na'ura mai ƙarfi, lokaci-lokaci ƙara ƙwanƙwasa ƙwan ƙwan ƙwan ƙwanƙwaran ƙwallon ƙafa.

Bincika tashin hankali na bel ɗin tuƙi a kowane kulawa. Ana daidaita tashin hankali na bel ta dunƙule 15 (Fig. 96, b). Tare da madaidaicin tashin hankali, juyawa a tsakiyar bel a ƙarƙashin ƙarfin 4 kg ya kamata ya kasance cikin 10-15 mm. Bayan daidaitawa, kulle dunƙule da goro 16.

Karanta kuma 8350 da 9370 Trailer Kulawa

Lokaci-lokaci, a lokacin da aka nuna a cikin ginshiƙi mai lubrication, duba matakin mai a cikin tafki mai haɓaka mai haɓaka mai ƙarfi, canza mai a cikin tsarin haɓaka na'ura mai ƙarfi, sannan wanke matatar tafki.

Kullum duba tsananin haɗin haɗin gwiwa da hatimin haɓakar hydraulic, famfo, bututu da hoses na tsarin.

Don tsarin tuƙin wutar lantarki, yi amfani da mai mai tsabta kawai, taceccen mai kamar yadda aka ƙayyade akan ginshiƙi mai laushi. Zuba mai a cikin tafki mai nisan mm 10-15 a ƙasan gefen sama na tafki ta mazurari tare da raga mai kyau biyu. Lokacin zuba mai, kada a girgiza ko motsa shi a cikin akwati.

Amfani da gurbataccen mai yana haifar da saurin lalacewa na silinda mai sarrafa wutar lantarki, masu rarrabawa da sassan famfo.

Lokacin duba matakin mai a cikin tafki na famfo a kowane kulawa (TO-1), dole ne a shigar da ƙafafun gaban mota madaidaiciya.

A kowane TO-2, cire tacewa daga tanki kuma kurkura. Idan matatar ta cika da yawa tare da taurin ajiya, wanke ta da fenti na mota. Kafin cire tacewa, tsaftace murfin tankin tarkace sosai.

Lokacin canza mai, wanda ake aiwatar da shi sau 2 a shekara (tare da kulawa na yanayi), ɗaga gatari na gaba na motar don kada ƙafafun su taɓa ƙasa.

Don zubar da mai daga tsarin, dole ne ku:

- cire haɗin tanki kuma, bayan cire murfin, zubar da man;

- cire haɗin nozzles daga bututun fitarwa da magudanar ruwa na mai rarrabawa kuma a zubar da mai daga famfo ta cikin su;

- sannu a hankali juya gardama zuwa hagu da dama har sai ya tsaya, zubar da mai daga silinda wutar lantarki.

Bayan an zubar da man, a zubar da tafki mai sarrafa wutar lantarki:

- cire tacewa daga tanki, wanke shi kamar yadda aka bayyana a sama;

- tsaftace tanki sosai daga ciki, cire alamun gurɓataccen mai;

- shigar da tacewa da aka wanke a cikin tanki;

- zuba man sabo a cikin tanki ta mazurari tare da raga mai kyau biyu sannan a jira har sai ya zube ta cikin nozzles.

Lokacin cika sabon mai, tabbatar da cire iska gaba ɗaya daga tsarin. Don wannan kuna buƙatar:

- ƙara man fetur zuwa tanki zuwa matakin da ake so kuma kada ku taɓa tsarin na kimanin minti biyu;

- fara injin kuma bar shi ya yi gudu a ƙananan gudu na minti biyu;

- a hankali juya sitiyarin sau 2 zuwa dama da hagu har sai iskar kumfa a cikin tafki ta tsaya. Idan ya cancanta, ƙara mai zuwa matakin da aka nuna a sama; sake shigar da murfin tanki da maɗaurarsa;

- juya ƙafafun dama da hagu, duba don sauƙi na tuƙi da kuma yabo mai.

Bincika madaidaicin fil ɗin ƙwallon tare da injin da ke gudana akan kowane TO-1, yana jujjuya sitiyarin agogon agogo da ƙima.

Dole ne babu wasa a cikin haɗin gwiwar taye. A cikin hinge na tuƙi tare da injin ya tsaya, wasan bai kamata ya wuce 4 mm ba, kuma tare da injin yana gudana - har zuwa 2 mm.

Na'urar da kuma aiki na mai kara kuzari

Ƙwararren hydraulic (Fig. 94) naúrar ce da ta ƙunshi mai rarrabawa da haɗin wutar lantarki. Tsarin hydraulic na mai haɓaka ya haɗa da famfo gear NSh-10E wanda aka ɗora akan injin mota, tankin mai da bututun mai.

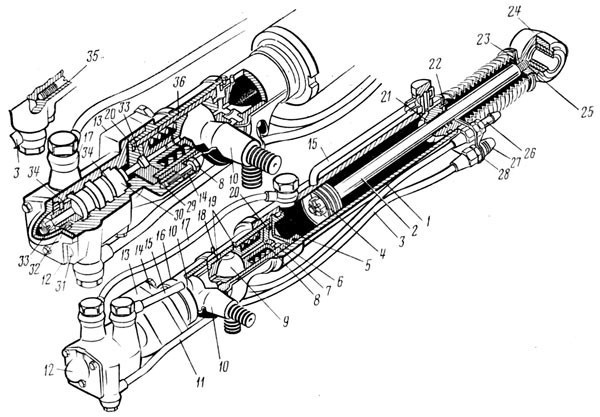

Shinkafa 94. GUR MAZ:

1 - Silinda wutar lantarki; 2 - sanduna; 3 - bututu mai fitarwa; 4 - fistan; 5 - kwalabe; 6 - jikin ball bearings; 7 - daidaitawa na baya na goro na haɗin gwiwa mai tsayi-tsaya; 8 - mai turawa; 9 - wani ball fil na daftarin tsayi; 10 - daure sanda ball fil; 11 - magudanar ruwa; 12 - murfin; 13 - gidaje masu rarraba; 14 - tudu; 15 - bututun reshe a cikin rami sama da piston na silinda mai ƙarfi; 16 - wani abin wuya na ɗaure mai shinge; 17 - bututun reshe a cikin rami na piston na silinda mai ƙarfi; 18 - mai; 19 - fil don gyara crackers; 20 - kulle kulle; 21 - murfin Silinda wutar lantarki; 22 - dunƙule; 23 - mai wanki na ciki don ɗaure murfin; 24 - tura kai; 25 - tukwane; 26 - ɗaure layin magudanar ruwa; 27 - taro na layin fitarwa; 28 - mariƙin bututu; 29 - daidaita saitin shugabannin haɗin gwiwar ƙwallon ƙafa na hannun tuƙi; 30 - kwanon rufi; 31 - kwalabe; 32 - kwanon rufi; 33 - ƙulli mai haɗawa; 34 - tashar haɗi; 35 - duba bawul; 36 - gilashin

Mai rarrabawa ya ƙunshi jikin mutum 13 da spool 30. Ana rufe daskararrun daskararrun da zoben rufewa na roba, ɗaya a cikin jiki kai tsaye, ɗayan kuma a cikin filogi 32 a cikin jiki kuma an rufe shi da hula 12.

Akwai tsagi guda uku na annular akan saman ciki na jikin nada. Matsanancin sun haɗa ta hanyar tashar zuwa juna kuma zuwa layin fitarwa na famfo, na tsakiya - ta hanyar magudanar ruwa zuwa tankin famfo. A saman drum akwai tsagi guda biyu na annular da aka haɗa ta hanyar haɗa tashoshi 34 tare da rufaffiyar kundin da ake kira reactive chambers.

Jikin nada yana haɗe zuwa flange na jiki tare da hinges 6. Akwai fil biyu na ball a cikin gidaje 6: 10, wanda aka haɗa sandar tuƙi, da 9, an haɗa su da sandar tuƙi mai tsayi. Duk yatsun biyu suna riƙe tsakanin biscuits masu siffar zobe ta hanyar toshe 29 da goro 7 mai daidaitawa ta hanyar maɓuɓɓugan ruwa. Ƙaddamar da biscuits yana iyakance ta masu turawa 8. An kiyaye hinges daga datti ta hanyar hatimin roba da aka gyara zuwa jiki tare da manne.

Yatsun da ke cikin wasu iyakoki na iya juyawa a cikin biscuits, waɗanda ke riƙe da filaye 19 da aka karye, waɗanda ke cikin ramukan biscuits.

Karanta kuma fasaha halaye na tsarin birki na tirela GKB-8350, OdAZ-9370, OdAZ-9770

An kafa bipod 36 a cikin kofin 10, wanda zai iya motsawa a cikin gidaje 6 a cikin jagorancin axial a cikin 4 mm. Wannan motsi yana iyakance da abin wuya 29 nannade cikin gilashi. Kafada a cikin matsananciyar matsayi yana dogara ne akan ƙarshen gidaje 13 na masu rarrabawa kuma a kan ƙarshen gidaje 6 na ƙwallon ƙwallon ƙafa. Spool 30 kuma tana motsawa da kofin 36, saboda an haɗa shi da ƙarfi ta hanyar ƙugiya da goro.

Silinda wutar lantarki 1 an haɗa shi zuwa ɗayan ƙarshen hinge jiki 6 ta hanyar haɗin zaren kuma an kulle shi da goro. Piston 4 yana motsawa a cikin silinda, an haɗa shi da goro zuwa sanda 2. An rufe piston da zoben ƙarfe na simintin gyare-gyare guda biyu. An rufe rami na silinda a gefe ɗaya tare da filogi 5, an rufe shi da zoben roba, a gefe guda, tare da murfin 21, an rufe shi da zobe iri ɗaya kuma an kiyaye shi tare da zobe mai riƙewa da mai wanki, wanda aka rufe murfin. An rufe tushe a cikin murfin tare da zoben roba wanda aka kiyaye shi ta hanyar scraper. A waje, tushen yana da kariya daga gurɓata ta takalmin roba. A ƙarshen sandar, an gyara shugaban 24 tare da haɗin zaren, wanda aka sanya katako da katako na karfe.

Ana gyara katako na roba a ƙarshen tare da ƙwanƙarar karfe na bushing da goro. Ramin Silinda wutar lantarki ya kasu ta fistan zuwa sassa biyu: karkashin-piston da kan-piston. Wadannan cavities an haɗa su ta hanyar reshe na 15 da 17 tare da tashoshi a cikin jikin mai rarrabawa, yana ƙarewa tare da tashoshi da ke buɗewa a cikin rami na jiki tsakanin raƙuman annular.

Ana iya haɗa cavities ɗin da ke ƙasa da sama da piston na silinda wutar lantarki ta hanyar bawul ɗin rajistan 35, wanda ya ƙunshi ball da maɓuɓɓugar ruwa da aka danna ta filogi.

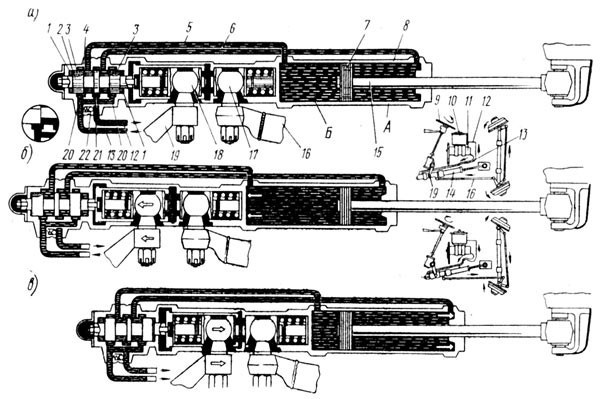

Ƙwararren hydraulic yana aiki kamar haka (Fig. 95). Lokacin da injin motar ke gudana, famfo 11 ya ci gaba da ba da mai zuwa ga mai haɓakawa na hydraulic 14, wanda, dangane da alkiblar motar, ya koma tanki 10 ko kuma an ciyar da shi cikin ɗayan cavities na aiki (A ko B) na Silinda wutar lantarki 8 ta hanyar bututu 5 da 6. Wani rami lokacin da aka haɗa ta layin magudanar ruwa 12 tare da tanki 10.

Matsakaicin mai ta hanyar tashoshi 3 a cikin spool 2 koyaushe ana watsa shi zuwa ɗakuna masu amsawa 1 kuma yana kula da motsa spool zuwa tsaka tsaki game da jiki.

Lokacin da abin hawa ke cikin madaidaiciyar layi (Fig. 95, a), famfo yana ba da mai ta hanyar bututun fitarwa 13 zuwa matsananciyar annular cavities 20 na masu rarrabawa, kuma daga can ta hanyar rata tsakanin gefuna na ramuka na spool. da gidaje zuwa tsakiyar annular cavity 21 da kuma kara tare da magudanar line 12 zuwa tanki 10.

Lokacin da aka juya sitiyarin zuwa hagu (Fig. 95, b) kuma zuwa dama (Fig. 95, c), madaidaicin madaidaicin 19 ta hanyar ƙwallon ƙwallon ƙwallon 18 yana cire spool daga tsaka-tsakin tsaka-tsaki da rami na 21 a cikin. spool jiki ya bambanta, kuma ruwa ya fara gudana a cikin daidaitaccen rami na wutar lantarki, yana motsa silinda 8 dangane da piston 7, wanda aka gyara akan sandar 15. Ana watsa motsi na silinda zuwa ƙafafun ƙafafun ta hanyar kwallon. fil 17 da sandar sitiyari mai tsayi XNUMX mai alaƙa da ita.

Idan ka daina jujjuya gardama 9, nada yana tsayawa kuma jiki yana motsawa zuwa gare shi, yana motsawa zuwa tsaka tsaki. Man ya fara zubewa a cikin tankin kuma ƙafafun sun daina jujjuyawa.

Mai haɓaka hydraulic yana da babban hankali. Don kunna ƙafafun motar, ya zama dole don matsar da spool ta 0,4-0,6 mm.

Tare da haɓaka juriya ga jujjuya ƙafafun, matsin mai a cikin rami mai aiki na silinda mai ƙarfi shima yana ƙaruwa. Wannan matsa lamba yana canjawa zuwa ɗakunan amsawa kuma yana kula da motsa spool zuwa matsayi na tsaka tsaki.

Shinkafa 95. Tsarin aiki GUR MAZ:

1 - dakin amsawa; 2 - kwanon rufi; 3 - tashoshi; 4 - gidaje masu rarraba; 5 da 6 - bututu; 7 - fistan; 8 - Silinda wutar lantarki; 9 - tuƙi; 10 - tanki; 11 - bam; 12 - bututun magudanar ruwa; 13 - matsa lamba tiyo; 14 - mai kara kuzari; 15 - sandar fistan; 16 - matsawa mai tsayi; 17 da 18 - yatsun ball; 19 - tuƙi lever; 20 - matsa lamba rami; 21 - magudanar ruwa; 22 - duba bawul

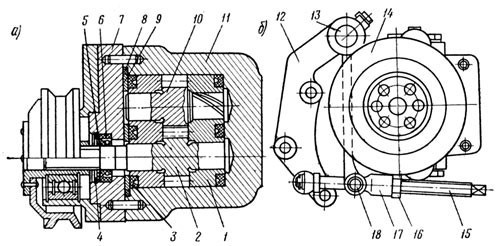

Shinkafa 96. Tutar wuta MAZ:

bam; b - na'urar tashin hankali; 1 - hannun dama; 2 - kayan aiki masu ƙarfi; 3 - zoben rufewa; 4 - zobe mai riƙewa; 5 - zoben tallafi; 6 - hannun riga; 7 - murfin; 8 - zoben rufewa; 9 - kayan aiki; 10 - hannun hagu; 11 - gidaje famfo; 12 - ƙayyadaddun tallafi; 13 - axis; 14 - kayan lambu; 15 - daidaita dunƙule; 16 - kullun; 17 - cokali mai yatsa; 18 - yatsa

Sakamakon haɓakar haɓakar haɓakar hydraulic, ƙarfin da ke kan sitiyarin a farkon jujjuya ƙafafun bai wuce kilogiram 5 ba, kuma matsakaicin ƙarfin shine kusan 20 kg.

Tsarin haɓaka na'ura mai ƙarfi yana da bawul ɗin aminci da aka sanya akan silinda mai ƙarfi. An saita bawul a masana'anta don matsa lamba na 80-90 kg / cm2. An haramta gyaran bawul a cikin jiragen ruwa.

Ya kamata a la'akari da cewa kawai aiki na ɗan gajeren lokaci na tuƙi yana ba da izinin lokacin da amplifier baya aiki, saboda wannan yana ƙaruwa da ƙoƙari akan tutiya kuma yana haɓaka wasansa na kyauta. Matsakaicin saurin abin hawa bai kamata ya wuce kilomita 20/h ba.

An shigar da famfo mai sarrafa wutar lantarki na NSh-10E (Fig. 96) a gefen hagu na injin kuma ana fitar da shi daga injin crankshaft ta amfani da V-belt. An ɗora tafki mai aiki akan firam ɗin radiyo.