Gwajin fitar da mai da injunan dizal a injuna guda ko injunan HCCI: Sashe na 2

Mazda ya ce za su kasance farkon waɗanda za su yi amfani da shi a cikin jerin

Tare da gas masu tsabta kamar fetur da ingancin dizal. Wannan labarin shine game da abin da ke faruwa yayin tsara injina ingantacce tare da haɗuwa iri ɗaya da daidaiton kai yayin matsewa. Masu zane kawai suna kiransa HCCI.

Tattara ilimi

Tushen irin waɗannan hanyoyin sun samo asali ne tun shekaru saba'in, lokacin da injiniyan Japan Onishi ya haɓaka fasaharsa "Konewa mai aiki a cikin yanayin zafi". A cikin yadi, 1979 shine lokacin rikicin mai na biyu kuma farkon hani na farko na doka game da yanayin muhalli, kuma burin injiniyan shine ya kawo baburan bugun bugun jini na gama gari a wancan lokacin daidai da waɗannan buƙatun. An sani cewa a cikin yanayin haske da ɓangaren kaya, ana adana babban adadin iskar gas a cikin silinda na raka'a biyu na bugun jini, kuma ra'ayin mai zanen Jafananci shine ya juyar da rashin amfaninsa ta hanyar ƙirƙirar fa'ida. Tsarin konewa wanda ragowar iskar gas da babban zafin mai ya haɗu don aiki mai amfani.

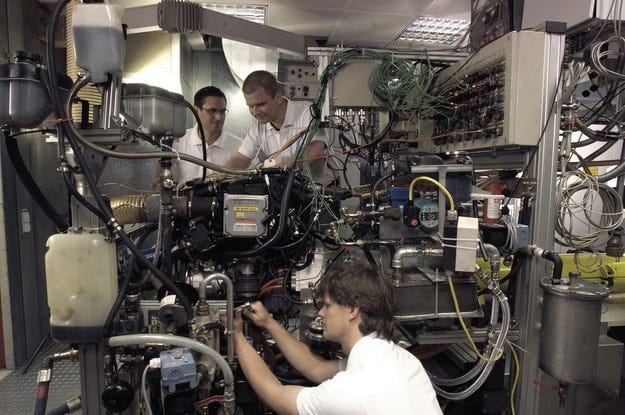

A karon farko, injiniyoyi daga tawagar Onishi sun sami damar aiwatar da kusan fasahar juyin juya hali a cikin kanta, wanda ya haifar da wani tsari na konewa ba tare da bata lokaci ba wanda da gaske ya sami nasarar rage hayakin hayaki. Duk da haka, sun kuma sami ci gaba sosai a cikin ingancin injin, kuma jim kaɗan bayan ƙaddamar da ci gaban, irin waɗannan hanyoyin sun nuna irin wannan tsari ta Toyota, Mitsubishi da Honda. Masu zanen kaya sun yi mamakin tsananin santsi kuma a lokaci guda konewa mai saurin gaske a cikin samfuran, rage yawan amfani da mai da hayaki mai cutarwa. A shekara ta 1983, samfurin farko na dakin gwaje-gwaje na injunan kunna wuta guda hudu ya bayyana, wanda ikon sarrafawa a cikin nau'ikan aiki daban-daban yana yiwuwa saboda gaskiyar cewa an san cikakken sinadarai da rabo daga cikin man da aka yi amfani da su. Duk da haka, nazarin waɗannan matakai na ɗan lokaci ne, tun da yake an dogara ne akan zaton cewa a cikin irin wannan nau'in inji ana aiwatar da su ne saboda motsin hanyoyin sinadarai, kuma irin waɗannan abubuwan da suka faru na jiki kamar haɗuwa da tashin hankali ba su da mahimmanci. A cikin 80s ne aka kafa harsashin ginin farko na ƙirar ƙididdiga na matakai dangane da matsa lamba, zafin jiki da ƙaddamar da abubuwan man fetur da iska a cikin ƙarar ɗakin. Masu zanen kaya sun yanke shawarar cewa za a iya raba aikin wannan nau'in injin zuwa manyan sassa biyu - ƙonewa da sakin makamashi na volumetric. Binciken sakamakon bincike ya nuna cewa kunna kai yana farawa ne ta hanyar matakan sinadarai na farko na ƙananan zafin jiki (wanda ke faruwa a ƙasa da digiri 700 tare da samuwar peroxides) waɗanda ke da alhakin konewa mai cutarwa a cikin injunan mai, da kuma hanyoyin fitar da babban makamashi. suna high-zazzabi. kuma ana yin su sama da wannan ƙayyadaddun yanayin zafi.

A bayyane yake cewa aikin ya kamata a mayar da hankali kan bincike da nazarin sakamakon canje-canje a cikin tsarin sinadaran da abun da ke ciki na cajin a ƙarƙashin rinjayar zafin jiki da matsa lamba. Saboda rashin iya sarrafa fara sanyi da aiki a matsakaicin nauyi a cikin waɗannan hanyoyin, injiniyoyi suna yin amfani da filogi. Gwajin aiki kuma yana tabbatar da ka'idar cewa inganci ya ragu yayin aiki tare da man dizal, tun da ma'aunin matsawa dole ne ya kasance ƙasa da ƙasa, kuma a mafi girman matsawa, tsarin kunnawa yana faruwa da wuri. matsawa bugun jini. A lokaci guda kuma, ya zama cewa lokacin amfani da man dizal, ana samun matsaloli tare da ƙazantar ɓarna na man dizal masu ƙonewa, da kuma yadda halayensu na zafin wuta ya fi fitowa fili fiye da gasoline na octane. Kuma mafi mahimmancin mahimmanci - ya bayyana cewa injunan HCCI suna aiki ba tare da matsaloli ba tare da har zuwa 50% na ragowar iskar gas a cikin gauraye masu dacewa a cikin silinda. Daga duk wannan ya biyo bayan cewa man fetur sun fi dacewa da aiki a cikin irin wannan raka'a kuma ana jagorantar ci gaba a wannan hanya.

Injini na farko kusa da ainihin masana'antar kera motoci, wanda aka aiwatar da waɗannan ayyukan cikin nasara a aikace, an gyara injunan VW 1,6-lita a 1992. Tare da taimakonsu, masu zanen kaya daga Wolfsburg sun sami damar haɓaka ƙimar aiki da kashi 34 cikin ɗari a kan kari. Nan gaba kadan, a shekarar 1996, kwatancen kwatankwacin injin HCCI tare da fetur da injin dizal din da aka yi allura kai tsaye ya nuna cewa injunan HCCI sun nuna mafi karancin amfani da mai da hayakin NOx ba tare da bukatar tsarin allura masu tsada ba. akan mai.

Meke faruwa a yau

A yau, duk da umarnin rage girman, GM na ci gaba da haɓaka injunan HCCI, kuma kamfanin ya yi imanin cewa irin wannan injin zai taimaka inganta injin mai. Irin wannan ra'ayi injiniyoyin Mazda ne suke da shi, amma za mu yi magana a kansu a fitowa ta gaba. Dakunan gwaje -gwaje na kasa na Sandia, suna aiki kafada da kafada da GM, a halin yanzu suna sabunta sabon aikin aiki, wanda shine bambancin HCCI. Masu haɓakawa suna kiransa LTGC don "Ƙaramin Zazzabin Man Fetur". Tun da a cikin ƙirar da ta gabata, hanyoyin HCCI an iyakance su zuwa takaitaccen yanayin aiki kuma ba su da fa'ida da yawa akan injunan zamani don rage girman, masana kimiyya sun yanke shawarar daidaita cakuda ta wata hanya. A takaice dai, don ƙirƙirar madaidaicin wuraren da matalauta da wadatattun wurare ke sarrafawa, amma sabanin ƙarin dizal. Abubuwan da suka faru a ƙarshen ƙarni sun nuna cewa yanayin yanayin aiki galibi bai isa ba don kammala halayen oxyidation na hydrocarbons da CO-CO2. Lokacin da cakuda ya wadata kuma ya ƙare, matsalar ta ƙare, tunda zafinsa yana ƙaruwa yayin aikin konewa. Koyaya, yana da ƙarancin isa don kada a fara ƙirƙirar ƙirar nitrogen. A ƙarshen ƙarni, masu zanen kaya har yanzu sun yi imanin cewa HCCI wani zaɓi ne mai ƙarancin zafin jiki ga injin dizal wanda bai samar da sinadarin nitrogen ba. Koyaya, ba a ƙirƙira su a cikin sabon tsarin LTGC ko dai. Hakanan ana amfani da man fetur don wannan dalili, kamar yadda yake a cikin samfuran GM na asali, saboda yana da ƙananan zafin zafin iska (kuma mafi haɗewa da iska), amma mafi girman yanayin zafin kai. Dangane da masu zanen dakin gwaje -gwaje, haɗin yanayin LTGC da kunna walƙiya a cikin mafi kyawun yanayi da wahalar sarrafa yanayin, kamar cikakken nauyi, zai haifar da injinan da suka fi inganci fiye da ragin raguwa na yanzu. Kamfanin Delphi Automotive yana haɓaka irin wannan tsarin ƙonewa. Suna kiran ƙirar su GDCI, don "Matsawa Ƙarfafawa Kai tsaye Man Fetur" (Gaskiyar Inji Kai Tsaye da Ƙarfafawa), wanda kuma ke ba da aiki mai ƙarfi da wadata don sarrafa tsarin konewa. A cikin Delphi, ana yin wannan ta amfani da allurai tare da rikitarwa na allurar allura, ta yadda, duk da raguwa da wadata, cakuda gaba ɗaya ta kasance mai raɗaɗi sosai don kada ta zama taushi, da ƙarancin zafin jiki ba don samar da sinadarin oxide na nitrogen ba. Masu zanen suna sarrafa sassa daban -daban na cakuda don su ƙone a lokuta daban -daban. Wannan tsari mai rikitarwa yayi kama da man dizal, iskar CO2 ba ta da yawa kuma samuwar sinadarin oxides na nitrogen ba sakaci bane. Delphi ya ba da ƙarin ƙarin ƙarin shekaru 4 na tallafin daga gwamnatin Amurka, kuma sha'awar masana'antun kamar Hyundai a cikin ci gaban su na nufin ba za su daina ba.

Bari mu tuna Disotto

Haɓaka masu zanen Labs na Binciken Injin Daimler a Untertürkheim ana kiransa Diesotto kuma a cikin farawa da matsakaicin yanayin lodi yana aiki kamar injin mai na gargajiya, ta amfani da duk fa'idodin allurar kai tsaye da turbocharging cascade. Koyaya, a ƙananan gudu zuwa matsakaici da lodi a cikin zagaye ɗaya, na'urorin lantarki za su kashe tsarin kunnawa kuma su canza zuwa yanayin sarrafa yanayin kunna kai. A wannan yanayin, matakai na shaye-shaye bawul suna canza halinsu sosai. Suna buɗewa a cikin ɗan gajeren lokaci fiye da yadda aka saba kuma tare da raguwa mai yawa - don haka kawai rabin iskar gas din suna da lokaci don barin ɗakin konewa, sauran kuma da gangan aka ajiye su a cikin silinda, tare da mafi yawan zafi da ke cikin su. . Don cimma ma fi girma zafin jiki a cikin dakuna, da nozzles allura wani karamin yanki na man fetur wanda ba ya ƙone, amma reacts da zafi gas. A lokacin bugun jini na gaba, ana allura sabon yanki na man fetur a cikin kowane silinda daidai adadin da ya dace. Bawul ɗin sha yana buɗewa a taƙaice tare da ɗan gajeren bugun jini kuma yana ba da damar daidaitaccen adadin iska mai kyau don shigar da silinda kuma a haɗe tare da iskar gas don samar da cakuda mai ɗanɗano mai ɗanɗano tare da adadin iskar gas mai yawa. Wannan yana biye da bugun bugun jini wanda zafin cakuda ke ci gaba da hauhawa har zuwa lokacin kunna kai. Ana samun madaidaicin lokacin aiwatarwa ta hanyar sarrafa adadin mai, iska mai kyau da iskar gas, bayanai akai-akai daga na'urori masu auna matsi da ke auna matsa lamba a cikin Silinda, da kuma tsarin da zai iya canza yanayin matsawa nan take ta hanyar amfani da tsarin eccentric. canza matsayi na crankshaft. A hanyar, aikin tsarin da ake tambaya bai iyakance ga yanayin HCCI ba.

Sarrafar da duk waɗannan hadaddun ayyuka na buƙatar sarrafa kayan lantarki waɗanda ba su dogara da tsarin yau da kullun na ƙayyadaddun algorithms waɗanda aka samo a cikin injunan konewa na ciki na al'ada, amma suna ba da damar sauye-sauyen aiki na ainihin-lokaci dangane da bayanan firikwensin. Ayyukan yana da wahala, amma sakamakon yana da daraja - 238 hp. Diesotto mai lita 1,8 ta ba da tabbacin manufar F700 tare da S-Class CO2 hayaki na 127 g/km da bin ka'idojin Euro 6 masu tsauri.

Rubutu: Georgy Kolev

Gida" Labarai" Blanks » Man Fetur da Injin Diesel a Injini ɗaya ko HCCI: Sashe na 2